April 12, 2017

Coming Soon: Tool Control

Our programmers have been working diligently on our next release – MAPCON 6.4. This release will bring quite a few enhancements and new features, but perhaps the most exciting thing it will bring is Tool Control.

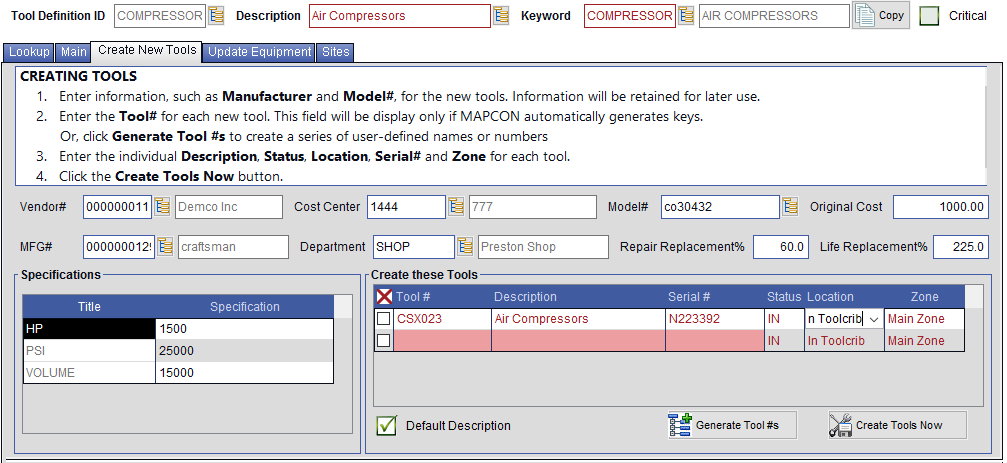

Tool Control will be part of the advanced maintenance module, and there will be a version for both Lite and Pro. It is meant to be used for tracking, repairing, and maintaining tools.

So, what can you do with Tool Control?

Plan tools.* When work orders are planned, tools can be added to the order so workers know which ones are required for the repair. This is helpful because it ensures the repair will get done in a more timely manner, since employees won’t have to try and guess what tools are needed for the repair. They can also make sure they can locate the tool before making the repairs, to save additional time.

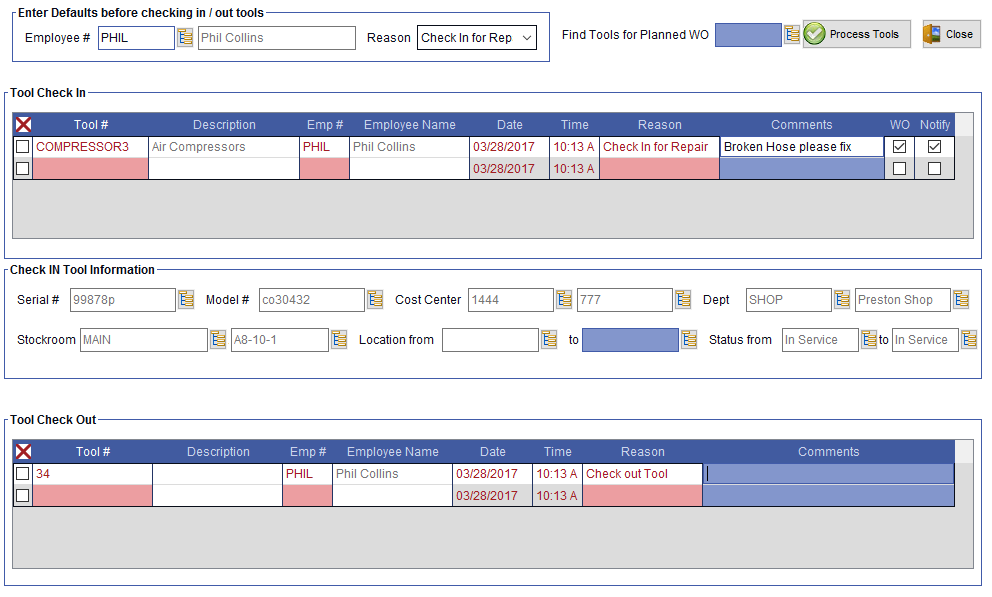

Maintain tools. Sometimes the tools we use to make repairs, need repairs. The Tool Control feature allows users to write work orders against a tool, and have them delivered to the correct person. Preventive Maintenance (PM) tasks can also be written against a tool. A PM on a tool could be something like sharpening or cleaning it. Regular preventive maintenance done on tools can help extend their lifetime.

Track tools. Another useful feature in Tool Control is tool tracking. When a critical machine goes down, a repair is needed immediately in order to prevent losses. If a tool needed to complete the repair cannot be found, downtime could be extended, thus causing financial losses. That’s why MAPCON's new Tool Control includes a screen where users can not only see where the tool is located, but what the status is. Additionally, the system has a spot for employee information which can be useful if a tool happens to go missing. Managers will know exactly who had it last, and can go directly to that person if it’s missing. Additionally, if the tool has been checked in to be repaired, the user that checked it in can be notified when the repair is completed.

Track costs.* Tool Control will allow users to track the cost of repairs done on a tool. It also has an added feature which will display screen notifications once the repair costs reach a certain overall percentage of the replacement cost. It also tracks the total cost of repairs done throughout the lifetime of a tool, and a report can be run on the tools to see where the repair costs are at. The lifetime repair costs can be shown on a report as well, which can help determine whether it is more cost efficient to buy a new tool, or repair the old one.

Retain history. Having history on tool repairs and cost can really help employees make decisions about when to replace tools. Tracking history can also help determine when PMs should be created and scheduled. For example, if history shows a belt in a tool breaks about every 3 months, workers can determine that pattern and then set up and schedule a PM to occur every 2.5 months to check the belt and replace it if needed. This can decrease tool downtime.

Tool Control is just one of the new features set to be released in 6.4. MAPCON will also have checklists, an enhanced menu generator, a faster report runner, and many others. Stay tuned to find out when 6.4 will be released!

*These features are only available in MAPCON Pro.