Published: April 24, 2012 | Updated: September 12, 2025

Published: April 24, 2012 | Updated: September 12, 2025

Preventative Maintenance Software – Training for Success

I am an experienced trainer of Computerized Maintenance Management System (CMMS) software. As most of you know, for the most part, CMMS entails the use of preventative maintenance software deployed in industrial installations such as manufacturing operations, or, facilities such as hospitals and schools to monitor and protect physical assets and capital equipment. This CMMS software is critical to preserving productivity as well as lowering operating costs by preventing equipment failure and unscheduled "downtime."

The Challenge of Effective CMMS Training

In my profession, a major consideration is not just the introduction of the CMMS concept, but the question of training a diverse user group at innumerable plants and facilities on how a specific preventative maintenance software package works for their unique operation. And, the answer is always a cagey, "It depends!"

Management is not likely (nor should they) to spend an inordinate amount of money on CMMS training classes specifically "customized" for the needs and expectations of such varied job classifications as, "planner," "draftsperson," "plant manager," or "safety director." Yet, each individual looks at their particular operational process through a different lens. Each has different responsibilities within the organization so daily work experiences vary widely. One thing though, that seems to help the trainer is to remember the rule used in public speaking, "Know your Audience."

Holistic Training Approach For CMMS Success

One solution frequently used to help the staff charged with varying degrees of maintenance responsibility to learn preventative maintenance software, is breaking the staff into subgroups with more or less unique lesson plans. Once again, this method is much more costly. It is also time-consuming. More importantly, it violates the entire CMMS principle

A better training approach is the holistic teaching method I favor wherein each person, regardless of staff position or duty, learns alongside the other so knowledge of the software and how it relates to their jobs function is shared with the whole team. Moreover, the entire group learns how preventative maintenance software operates across the entire operation with each level interacting to make the system flow perfectly.

Integration of CMMS Modules For Training

Integration of CMMS Modules For Training

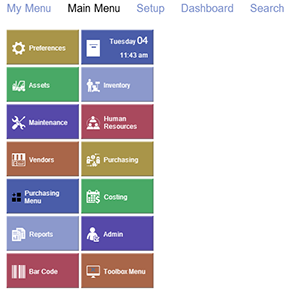

A great example of this concept is to place the integration of preventative maintenance software "modules" at the forefront of the training schedule demonstrating how the system operates. If you are a Maintenance Planner for instance, wouldn't it be a natural extension to have Inventory and Purchasing available? Premium CMMS software always offers this type of module availability. In fact, this is one of the primary reasons that a good CMMS software package beats an enterprise resource planning (ERP) package every time. Working across departments is part of a planner's day. The planner would be sadly inefficient if Inventory and Purchasing were independent of the operation’s preventative maintenance software.

Maintenance Planners To Assist With Your Operations

A good CMMS software will help the planner when:

- Checking availability of parts;

- Checking on the location of parts, and perhaps then pulling parts to a separate "staging" area;

- Reserving spare parts to the Work Order;

- Parts are not available in the storeroom by being proactive and initiating a Purchase Request; and,

- Directly initiating a Purchase Order to purchase parts (or a manual Purchase Request).

In closing, getting the most from your CMMS preventative maintenance software entails using the system as it was intended and training staff to use it as a team!

*What type of training works best for your operations? Check MAPCON training options.*

FAQs

What is preventative maintenance software?

Preventative maintenance software helps organizations reduce downtime and extend equipment life by scheduling and tracking maintenance tasks.

How does CMMS improve productivity?

CMMS improves productivity by reducing unexpected equipment failures and streamlining maintenance workflows.

What makes MAPCON CMMS different from ERP systems?

MAPCON CMMS offers specialized maintenance modules like Inventory and Purchasing that integrate seamlessly, unlike ERP systems that are often less flexible.

Why is training important for CMMS success?

Training ensures that all staff understand how the system works across departments, leading to better teamwork and efficiency.

Can CMMS be customized for different roles in a facility?

Yes, CMMS can be adapted to meet the needs of planners, managers, and technicians, though MAPCON recommends a holistic training approach for maximum impact.

How do CMMS modules help maintenance planners?

Modules such as Inventory and Purchasing assist planners in checking parts availability, reserving materials, and initiating purchase orders.