Published: September 17, 2014 | Updated: December 15, 2025

Published: September 17, 2014 | Updated: December 15, 2025

Drive Maintenance Success: 8 Efficiency Insights for Your Crew

You work in the demanding world of maintenance. You understand how maximizing every minute improves operations. Maintenance managers face a constant barrage of tasks and potential disruptions, making it challenging to maintain momentum. With eight efficiency insights for your crew in this article, you can better understand how to drive maintenance success. We'll delve into each quote, dissect its meaning, and discuss how to apply these principles to your daily maintenance routines.

Unconventional Wisdom: Finding Easier Paths

Unconventional Wisdom: Finding Easier Paths

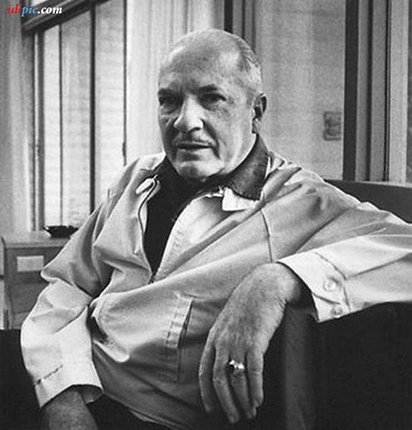

Our journey begins with a seemingly paradoxical concept from Robert A. Heinlein: "Progress isn't made by early risers. It's made by lazy men trying to find easier ways to do something." This quote challenges the notion that hard work always equates to long hours. Instead, it emphasizes the value of intelligent problem-solving.

When faced with a daunting task, resist the urge to dive in headfirst. Instead, take a moment to consider if there's a simpler, more effective approach. By embracing a "lazy" mindset, you encourage innovation and uncover hidden efficiencies. Think of it as strategic simplification. For example, instead of manually inspecting every piece of equipment, consider implementing sensor technology to monitor critical parameters remotely.

Avoiding Pitfalls: Knowing When to Stop

Denis Healey's "Healey's First Law of Holes: When in one, stop digging," provides a critical lesson in recognizing when a strategy isn't working. In maintenance, this translates to acknowledging when a troubleshooting approach proves ineffective. Don't waste valuable time and resources pursuing a dead end. Instead, learn to pivot and explore alternative solutions. If a particular repair method consistently fails, investigate the root cause and consider a different approach. Recognizing when to change course is a hallmark of effective maintenance management.

Focusing on Value: Eliminating Unnecessary Tasks

Peter Drucker's insightful observation, "Nothing is less productive than to make efficient what should not be done at all," highlights the importance of prioritizing tasks. You can easily get caught up in the details and expend energy on activities that don't contribute to overall goals. Before refining a process, evaluate the necessity of the refinement and the process itself. Eliminate redundant tasks and focus on activities that directly impact productivity and reliability. For instance, instead of meticulously documenting every minor repair, focus on creating detailed records for critical equipment failures.

Discover how streamlined maintenance processes can elevate production. Learn more.

The Power of Delegation: Leveraging Team Strengths

J. Paul Getty's quote, "I'd rather have one percent of the efforts of 100 people than 100 percent of my own efforts," underscores the importance of delegation. As a maintenance manager, you oversee the big picture and try not to get bogged down in minutiae. Empower your team members by assigning tasks that align with their skills and expertise. This frees you to focus on strategic planning and process improvement. For example, delegate routine inspections to experienced technicians, allowing you to concentrate on developing preventative maintenance strategies.

Swift Action: Addressing Problems Directly

Swift Action: Addressing Problems Directly

H. Ross Perot's direct advice, "If you see a snake, just kill it. Don't appoint a committee on snakes," encourages decisive action. When faced with an obvious problem, address it immediately. Don't delay or overcomplicate the solution. If a piece of equipment consistently malfunctions, don't wait for a formal review. Take immediate steps to repair or replace it. Addressing issues promptly minimizes downtime and prevents further complications.

Simple Solutions: Embracing Practicality

Jimmy Carter's simple yet effective suggestion, "Put on a sweater," reminds us that sometimes the most straightforward solutions are the best. In maintenance, this translates to embracing practicality and avoiding unnecessary complexity. If a piece of equipment overheats, ensure proper ventilation before resorting to costly repairs. Simple solutions can often yield significant results. Don’t always search for complex fixes, sometimes a basic solution will work.

Leading with Kindness: Fostering Respect

Charles Schwab's emphasis on kindness, "Kindness is more powerful than compulsion," highlights the importance of fostering a positive work environment. Treating your team with respect and empathy cultivates trust and loyalty. Avoid resorting to harsh criticism or punitive measures. Instead, provide constructive feedback and recognize their contributions. A positive atmosphere increases morale and productivity.

Recognizing Contributions: Valuing Your Team

Mary Kay Ash's advice, "Everyone wants to be appreciated, so if you appreciate someone, don't keep it secret," underscores the power of recognition. Acknowledging your team's hard work and dedication boosts morale and motivates them to perform at their best. Publicly recognize their achievements and express gratitude for their efforts. Acknowledgment helps build a positive team environment.

Integrating CMMS for Enhanced Efficiency

To truly maximize efficiency, consider integrating a Computerized Maintenance Management System (CMMS). A CMMS provides a centralized platform for managing maintenance tasks, tracking equipment performance, and scheduling preventative maintenance. It allows you to automate workflows, reduce paperwork, and improve communication among team members. By leveraging a CMMS, you can effectively implement the principles outlined in these quotes, such as prioritizing tasks, delegating responsibilities, and addressing problems promptly. A CMMS enables you to see the real-time data and plan for the future. The data gathered from a CMMS will help to find those "snakes" that need immediate attention, and help with delegation to the right team members.

FAQs

How can maintenance managers improve efficiency without overworking their crews?

Efficiency comes from smart strategies like task prioritization, delegation, and using technology such as CMMS, not from working longer hours.

Why is it important for maintenance teams to know when to change course?

Recognizing when a method isn’t working prevents wasted time and resources, allowing teams to pivot and find effective solutions quickly.

What role does delegation play in successful maintenance management?

Delegating tasks empowers team members, utilizes their strengths, and allows managers to focus on strategic planning and process improvement.

How does kindness and recognition impact maintenance crew performance?

Respect, empathy, and appreciation boost morale, foster loyalty, and motivate team members to perform at their best.

Why should maintenance teams embrace simple solutions when possible?

Straightforward fixes often save time and money, preventing unnecessary complexity and minimizing downtime.

How can a CMMS help maintenance teams implement efficiency strategies?

A CMMS streamlines scheduling, automates workflows, tracks equipment data, and improves communication, making it easier to apply efficiency principles effectively.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!