Published: October 06, 2014 | Updated: September 16, 2025

Published: October 06, 2014 | Updated: September 16, 2025

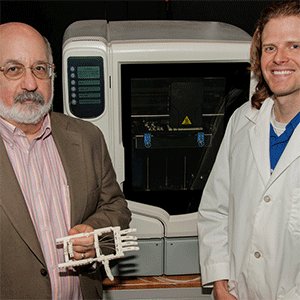

Additive Manufacturing: The Future of Production

Understanding the Fundamentals of Additive Manufacturing

Understanding the Fundamentals of Additive Manufacturing

Often referred to as 3D printing, additive manufacturing involves constructing three-dimensional objects layer by layer from digital models. This process contrasts sharply with traditional subtractive manufacturing, where material gets removed from a larger block. Imagine constructing a complex gear not by carving it from a metal block, but by depositing metal powder precisely where needed, layer by layer, until the final shape emerges. This method allows for intricate designs and customized parts that were previously impossible or prohibitively expensive to produce. Let's delve into one aspect of the future of production.

From Science Fiction to Industrial Reality

The technology, while rooted in the late 20th century, has seen rapid advancements, moving beyond simple prototypes to functional, end-use parts. The concept of instantly creating objects from digital blueprints once belonged to the realm of science fiction, reminiscent of the replicators in "Star Trek." While we may not yet have food replicators, the reality of additive manufacturing is rapidly approaching that level of transformative potential.

Instead of relying on traditional production lines, businesses can now explore on-demand manufacturing, creating products tailored to specific needs. This shift encourages a move away from mass production toward mass customization. Consider a scenario where a manufacturer produces custom prosthetic limbs tailored to individual patients, or a car company creates bespoke parts for classic vehicles.

The Impact on Manufacturing and Beyond

The manufacturing sector will continue to see a profound shift due to additive manufacturing. The ability to produce complex geometries without the need for extensive tooling reduces lead times and costs. You'll see this particularly transformative benefit in industries like aerospace, with the production of lightweight but high-strength components.

For example, aircraft manufacturers use 3D-printed titanium parts to reduce weight and improve fuel efficiency. Furthermore, this technology empowers decentralized production, enabling companies to manufacture parts closer to the point of use, reducing transportation costs and environmental impact.

Aerospace and Automotive Applications

In aerospace, additive manufacturing allows for the creation of complex turbine blades and engine components with improved performance characteristics. By producing parts with optimized internal structures, manufacturers can achieve significant weight reductions and performance enhancements. Imagine creating a turbine blade with internal cooling channels that were previously impossible to manufacture with traditional methods. The result: More efficient jet engines. The automotive sector also benefits from this technology, creating custom parts for high-performance vehicles and producing tooling on demand.

Medical Advancements and Personalized Healthcare

The medical field experienced a revolution with additive manufacturing. Custom implants, prosthetics, and surgical guides are now produced with unprecedented precision. Surgeons use 3D-printed models of patient organs to plan complex procedures, reducing risks and improving outcomes. Imagine a surgeon using a 3D-printed model of a patient's heart to practice a complex procedure before operating on the actual patient.

Furthermore, bioprinting, a specialized form of additive manufacturing, holds the promise of creating functional tissues and organs for transplantation. Bioprinting allows researchers to layer bio-inks, made of living cells, to build complex structures. This shows a giant step towards personalized regenerative medicine.

Construction and Infrastructure

The construction industry can also adopt additive manufacturing to build houses and infrastructure components. 3D-printed concrete structures offer faster construction times and reduced material waste. Large-scale 3D printers can construct entire buildings layer by layer, opening up possibilities for affordable housing and rapid deployment in disaster relief situations.

Consider a scenario where a 3D printer builds a low-cost house in a remote area, significantly reducing construction time and costs. This technology also allows for the creation of complex architectural designs that were previously impossible to achieve with traditional construction methods.

Overcoming Challenges and Looking Ahead

Despite its vast potential, additive manufacturing faces challenges. They include material limitations, production speeds, and the need for skilled labor. Ensuring consistent quality and reliability in 3D-printed parts requires advanced monitoring and control systems. The complexity of 3D models, which contain massive datasets, demands sophisticated software and powerful computing resources. Additionally, the cost of materials, which varies greatly depending on the type of material and the complexity of the part, can pose a significant barrier to widespread adoption. However, ongoing research and development are addressing these challenges, leading to faster printing speeds, a wider range of printable materials, and improved process control.

Future Trends and Innovations

Looking ahead, additive manufacturing will continue to evolve, driven by advancements in materials science, software, and automation. Hybrid manufacturing, which combines additive and subtractive processes, will enable the creation of even more complex and functional parts. The integration of artificial intelligence and machine learning will allow for real-time process monitoring and control, ensuring consistent quality and reliability.,/p>

As the technology matures, we can expect to see wider adoption across various industries, leading to more efficient, sustainable, and personalized manufacturing practices. The ability to create on-demand, customized products will reshape supply chains and revolutionize consumer experiences.

While the dream of instantaneous object creation still lies in the future, additive manufacturing is undeniably transforming numerous industries, driving innovation, and creating new possibilities. The future holds immense potential for this technology, promising to reshape how we design, produce, and consume products.

For more information on additive manufacturing, read the article from Jabil.

FAQs

What is additive manufacturing and how does it differ from traditional methods?

Additive manufacturing, or 3D printing, builds objects layer by layer from digital models, unlike traditional subtractive methods that remove material from a block.

Which industries benefit most from additive manufacturing?

Industries such as aerospace, automotive, medical, and construction benefit from 3D printing due to faster production, customization, and reduced costs.

How is additive manufacturing transforming healthcare?

3D printing enables custom prosthetics, implants, surgical guides, and even advances in bioprinting, paving the way for personalized healthcare solutions.

What role does additive manufacturing play in aerospace and automotive industries?

It allows manufacturers to produce lightweight, high-strength parts with complex geometries, improving performance and fuel efficiency.

What challenges does additive manufacturing face today?

Current challenges include material limitations, high costs, slower production speeds, and ensuring consistent quality and reliability.

What does the future of additive manufacturing look like?

Future trends include hybrid manufacturing, AI-driven quality control, wider material availability, and greater adoption across global industries.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!