Published: June 26, 2025 | Updated: October 23, 2025

Published: June 26, 2025 | Updated: October 23, 2025

Proactive Management: Moving Beyond Reactive Habits

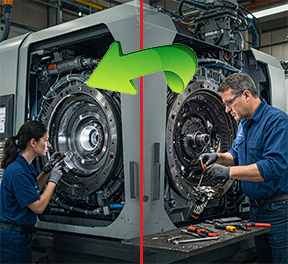

The concept of a proactive personality garners significant attention across various fields. Inspired by a discussion on proactive maintenance from Maintenance World, this exploration delves deeper into the nuances of adopting a forward-thinking approach. While the initial article presented a valuable perspective, this discussion aims to broaden the understanding and address specific points, particularly the notion of a shift in perspective from reactive habits. A thoughtful examination reveals that transitioning to a proactive stance involves more than just speed; it requires a fundamental change in mindset and consistent application across different aspects of life.

The concept of a proactive personality garners significant attention across various fields. Inspired by a discussion on proactive maintenance from Maintenance World, this exploration delves deeper into the nuances of adopting a forward-thinking approach. While the initial article presented a valuable perspective, this discussion aims to broaden the understanding and address specific points, particularly the notion of a shift in perspective from reactive habits. A thoughtful examination reveals that transitioning to a proactive stance involves more than just speed; it requires a fundamental change in mindset and consistent application across different aspects of life.

The Risks of a Reactive approach in Daily Life and Work

Many individuals and organizations find themselves trapped in a reactive cycle. This "if it ain't broke, don't fix it" mentality, as highlighted in the Maintenance World article, often stems from perceived constraints of time, money, and effort. At home, this might manifest as delaying minor repairs or neglecting routine upkeep. In the workplace, it translates to postponing preventive maintenance tasks in favor of addressing immediate operational demands.

This approach, however, carries significant risks. Neglecting potential issues invariably leads to more significant problems down the line. A small leak can escalate into major water damage, and deferred maintenance on equipment can result in costly breakdowns and production halts. When forced to react to these crises, decisions are often rushed, potentially flawed, and ultimately more expensive.

Spotting Everyday Acts of Proactive Management

The journey toward a more proactive stance doesn't necessarily involve a complete overhaul of behavior. In reality, most people already engage in proactive actions, often without conscious recognition. Consider the routine maintenance of a vehicle, such as oil changes and tire rotations. These actions prevent larger, more expensive problems. Similarly, personal health practices like annual physicals and daily dental hygiene serve as preventive measures against future health issues. These everyday examples demonstrate an inherent understanding of the benefits of proactive behavior. The challenge lies in extending this understanding and applying it more broadly to other areas of life, both personal and professional.

What Holds Us Back from Proactivity in Management?

Time Constraints: A Matter of Prioritization

The perception of insufficient time frequently acts as a major deterrent to proactive behavior. Individuals might readily allocate time for short-term, immediate needs but hesitate to invest time in preventive measures that yield long-term benefits. Brushing teeth for two minutes daily feels manageable, while dedicating time for home inspections or smoke alarm checks often gets postponed.

Similarly, in a professional setting, maintenance teams might feel overwhelmed with immediate repairs, leaving little room for scheduled preventive maintenance. Production teams might resist downtime for maintenance, prioritizing immediate output. However, a proactive approach, while requiring an initial time investment, ultimately saves time by mitigating larger, more time-consuming emergencies.

Financial Trade-Offs: Cost vs. Value of Proactivity

Budgetary constraints often present another perceived obstacle to proactive measures. Individuals might readily purchase everyday consumables but balk at the cost of preventive maintenance supplies or professional inspection services. This short-sighted view can lead to significant financial burdens when neglected issues eventually require extensive and expensive repairs.

In a business context, the initial investment in spare parts inventory for preventive maintenance might seem like an added expense. However, this cost pales in comparison to the financial repercussions of unexpected downtime, expedited parts shipments, and lost production. A proactive financial strategy recognizes preventive maintenance as an investment that yields substantial returns by minimizing costly reactive repairs.

The Effort Factor: Overcoming Inertia

The perceived effort involved in proactive tasks can also contribute to inaction. The immediate gratification of completing a reactive repair might feel more tangible than the seemingly less urgent tasks of preventive maintenance. Trimming a tree branch near a power line requires effort that might be deferred until a storm causes a power outage. Similarly, in the workplace, the effort required for maintenance teams to schedule and perform routine tasks and for production teams to collaborate on asset management can feel burdensome. Overcoming this inertia requires a shift in perspective, recognizing that the effort invested in proactive measures is significantly less than the effort required to address major failures and their consequences.

Fostering Proactivity in Management Culture

The transition from a reactive to a proactive culture within an organization necessitates a fundamental change in thinking. The "if nothing is wrong, why bother" mentality must give way to an understanding that consistent preventive measures actively safeguard against future problems. This shift begins with acknowledging the existence of potential issues and recognizing the tangible benefits of proactive maintenance. Educating employees across all levels about these benefits and fostering a shared understanding of the long-term advantages proves crucial in gaining buy-in and encouraging participation.

Real-World Lessons in Proactive Thinking

Gaining perspective from different sources can clarify the principles of proactive behavior in a professional setting. Think about soliciting feedback in the workplace. Similar to how equipment needs regular upkeep, work processes improve through consistent attention and effort. Teams, like individuals, can become complacent and rely on routine methods. Seeking feedback proactively serves as a measure to identify potential weaknesses and enhance performance. While individual opinions might differ, consistent feedback from multiple sources highlights areas that need attention and refinement. Likewise, in maintenance, engaging a wider team in creating proactive strategies incorporates varied viewpoints and strengthens the overall plan.

Gaining perspective from different sources can clarify the principles of proactive behavior in a professional setting. Think about soliciting feedback in the workplace. Similar to how equipment needs regular upkeep, work processes improve through consistent attention and effort. Teams, like individuals, can become complacent and rely on routine methods. Seeking feedback proactively serves as a measure to identify potential weaknesses and enhance performance. While individual opinions might differ, consistent feedback from multiple sources highlights areas that need attention and refinement. Likewise, in maintenance, engaging a wider team in creating proactive strategies incorporates varied viewpoints and strengthens the overall plan.

Why Words Matter: Language and Proactive Mindsets

Even seemingly minor aspects, such as the language used, can significantly impact the adoption of a proactive mindset. The Maintenance World article touched upon the misconception that once equipment undergoes work, no further attention is necessary. This highlights the importance of distinguishing between "repair" and "maintenance." Repair often implies a one-time fix, while maintenance denotes an ongoing process. An example related to small engine repairs underscores this distinction. Customers often believe the mechanic "fixes" their engines permanently, failing to grasp the need for regular upkeep. Similarly, routine health check-ups for pets are considered preventive "maintenance," not a one-time "fix." Emphasizing the continuous nature of maintenance helps to cultivate a proactive understanding.

Strategies to Strengthen Proactive Management

Make Time for Preventive Thinking

Adopting a proactive mindset requires a conscious effort to allocate time for preventive measures. Just as important tasks receive scheduling priority, preventive maintenance should become an integral part of the workflow. By proactively scheduling these tasks, organizations and individuals will ultimately spend less time addressing urgent and emergency situations. Consistent preventive maintenance reduces the frequency and severity of unexpected problems, freeing up valuable time in the long run.

Budgeting for Long-Term Maintenance Success

While the initial investment in preventive maintenance inventory and activities might appear to increase costs, a long-term perspective reveals significant financial advantages. The expenses associated with unplanned downtime, expedited shipping of replacement parts, and emergency repairs far outweigh the cost of maintaining a proactive inventory and schedule. Organizations that strategically allocate resources to preventive maintenance will experience a leveling off of inventory costs and a substantial reduction in overall operational expenses.

FAQs

What is proactive management in maintenance?

Proactive management focuses on preventing problems before they occur through consistent planning, inspections, and preventive maintenance.

How does reactive management create risks for businesses?

Reactive management delays maintenance until failures occur, leading to costly downtime, rushed decisions, and higher repair expenses.

What are common barriers to proactive management?

Time constraints, perceived costs, and the effort required for preventive measures often hold teams back from proactive management.

How can organizations foster a proactive culture?

By educating employees on the benefits of preventive maintenance, allocating time for planning, and encouraging consistent proactive actions.

Why is feedback important for proactive management?

Proactively seeking feedback identifies potential weaknesses, improves processes, and strengthens preventive strategies across teams.

How can MAPCON CMMS support proactive maintenance strategies?

MAPCON CMMS helps schedule preventive tasks, track maintenance history, and manage inventory, reducing emergency repairs and downtime.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!