Published: July 21, 2014 | Updated: September 16, 2025

Published: July 21, 2014 | Updated: September 16, 2025

How Six Manufacturing Visionaries Reshaped Industry

The article highlights how six manufacturing visionaries reshaped industry. Their efforts continue to influence operations in factories, organizations, and global markets. Each pioneer contributed innovations that advanced efficiency, coordination, and productivity on a massive scale. This discussion goes deeper, analyzing how these leaders altered the very DNA of manufacturing—and how today's digital tools, like a computerized maintenance management system (CMMS) could have enhanced their revolutionary work.

The article highlights how six manufacturing visionaries reshaped industry. Their efforts continue to influence operations in factories, organizations, and global markets. Each pioneer contributed innovations that advanced efficiency, coordination, and productivity on a massive scale. This discussion goes deeper, analyzing how these leaders altered the very DNA of manufacturing—and how today's digital tools, like a computerized maintenance management system (CMMS) could have enhanced their revolutionary work.

Henry Ford and the Birth of the Assembly Line

Few names echo through the corridors of manufacturing history like Henry Ford. In 1913, Ford introduced the world’s first moving assembly line for automobile production, forever changing how complex goods were manufactured. Drawing inspiration from flour mills and breweries, Ford didn't invent the idea of continuous production—but he scaled it into a system that assembled an entire car in under three hours.

This innovation lowered vehicle costs and made car ownership accessible for the average American. It also catalyzed a broader shift toward repetitive task specialization, where each worker mastered a single function within a larger workflow. By doing so, Ford slashed production times and multiplied factory output.

If a Computerized Maintenance Management System (CMMS) had existed during Ford’s era, machine upkeep and downtime tracking might have evolved just as rapidly as the product itself. His assembly line depended on machinery running without interruption. A CMMS could have automated maintenance scheduling and flagged equipment issues before failures halted production.

Frederick Taylor and the Pursuit of Peak Efficiency

Frederick Taylor shaped early management with a data-centric approach known as scientific management. By timing workers with a stopwatch and breaking down their tasks, Taylor aimed to find the most efficient way to complete each step of a process. His meticulous studies helped define the modern industrial engineer’s toolkit.

Taylor’s belief in standardization and precision provided the blueprint for countless manufacturing improvements. His principles directly influenced Ford and set a precedent for later thinkers focused on measurable outcomes.

In today’s factories, a CMMS embodies Taylor’s ideals. It enables time-stamped logs of maintenance activity, calculates machine efficiency, and helps eliminate wasteful redundancy. Taylor sought predictable, measurable output; a modern CMMS delivers exactly that by transforming work orders and machine care into trackable, digital workflows.

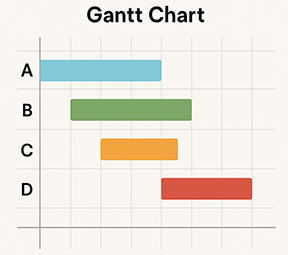

Henry Gantt: Visual Thinking in Project Execution

Though lesser known to the public, Henry Gantt fundamentally altered project management with his namesake—the Gantt chart. These visual timelines appeared during World War I but soon proved indispensable for civilian megaprojects like the Hoover Dam and the U.S. highway system.

Though lesser known to the public, Henry Gantt fundamentally altered project management with his namesake—the Gantt chart. These visual timelines appeared during World War I but soon proved indispensable for civilian megaprojects like the Hoover Dam and the U.S. highway system.

Gantt’s innovation let managers see project sequences and dependencies clearly. That visibility meant tighter control of budgets, deadlines, and labor coordination. Teams could anticipate conflicts, manage scope changes, and ensure efficient task completion.

How CMMS Tools Build on Gantt’s Ideas

A CMMS can apply Gantt’s methodology to maintenance planning. For example, it can visualize preventive maintenance schedules, highlight resource overlaps, and track task durations. The same clarity that helped Gantt build dams can help today’s manufacturers prevent costly equipment failures.

Henri Fayol’s Foundation of Modern Management

Henri Fayol developed one of the earliest and most comprehensive frameworks for business administration. His 14 principles—such as Division of Work and Unity of Direction—still anchor much of management education today.

Fayol advocated clear lines of communication and authority, with structured hierarchies that could scale. His work complemented that of Taylor and Gantt, moving the conversation from the factory floor to executive offices.

Incorporating CMMS into Fayol’s structure would have supported his concepts of order and discipline. The software enforces systematic logging, assigns accountability, and creates traceable maintenance histories. Fayol’s vision of a well-oiled administrative machine becomes more tangible through digital maintenance systems.

Discover how streamlined maintenance processes can elevate production. Learn more.

John Welch: Turning Performance into a Culture

John F. Welch, often remembered for reshaping General Electric (GE), didn't invent a tool or chart. He altered company culture. Welch insisted on measurable performance and brutal honesty. He regularly cut underperforming executives, restructured teams, and demanded continuous innovation.

Under Welch’s leadership, GE embraced rapid decision-making and leaned heavily on data to guide business moves. His “workouts”—collaborative sessions to eliminate bureaucracy—became legendary for removing inefficiencies and empowering employees.

Where a CMMS Fits into Welch’s Model

Welch’s obsession with data would find a perfect partner in CMMS software. A centralized system allows executives to examine asset histories, work order metrics, and equipment reliability—all in real time. The transparency aligns with Welch’s belief in informed decision-making and performance tracking.

Michael Dell and the Age of Custom Supply Chains

Michael Dell revolutionized not just computing but the very idea of how products reach consumers. By cutting out the middleman and offering direct-to-consumer customization, Dell forced a rethinking of traditional supply chain models.

Michael Dell revolutionized not just computing but the very idea of how products reach consumers. By cutting out the middleman and offering direct-to-consumer customization, Dell forced a rethinking of traditional supply chain models.

His approach required agile manufacturing systems that adapted quickly to changes in demand and component availability. This flexibility depended on rapid data sharing across departments and geographies.

Had CMMS platforms been integrated into Dell’s operations from the start, they could have ensured that the factories producing customized devices ran with minimal interruption. Detailed equipment records and preventive maintenance would have supported the speed and precision that Dell’s model demanded.

The Role of Digital Tools in Manufacturing Legacy

These six figures laid the groundwork for industrial progress by rethinking how labor, tools, and strategy intersect. Yet modern challenges—cybersecurity, labor shortages, sustainability—require tools they couldn’t have imagined.

Enter CMMS. These systems bridge the visionary efforts of the past with the technological demands of the present. CMMS applications log technician actions, predict machine failures, and allocate resources based on real-time analytics. They extend the life of equipment, reduce unexpected downtime, and keep factories aligned with performance goals.

The pioneers discussed here believed in measurement, process clarity, and the unrelenting pursuit of improvement. A CMMS doesn’t replace their wisdom—it reinforces and evolves it.

The Future Calls for New Innovators

Industrial progress never rests. The world now faces automation, climate change, and AI-led decision-making. While these challenges feel complex, the need for clear systems, effective leadership, and measured performance remains unchanged. Future innovators might not invent assembly lines or management principles—but they will adapt legacy frameworks for tomorrow’s world.

FAQs

Who were some of the key visionaries that reshaped manufacturing?

Henry Ford, Frederick Taylor, Henry Gantt, Henri Fayol, John Welch, and Michael Dell significantly influenced manufacturing efficiency, management, and supply chain innovation.

How did Henry Ford revolutionize production processes?

Ford introduced the moving assembly line, drastically reducing production time and increasing factory output.

What role does a CMMS play in modernizing historical manufacturing principles?

A CMMS tracks maintenance, schedules preventive work, monitors equipment efficiency, and enforces accountability, bringing historical efficiency concepts into today’s digital operations.

Can MAPCON’s CMMS enhance workflow inspired by Gantt and Welch?

Yes, MAPCON’s CMMS visualizes preventive maintenance schedules, tracks tasks, and provides real-time performance metrics, supporting structured project and operations management.

Why is preventive maintenance crucial for efficient manufacturing?

Preventive maintenance minimizes downtime, extends equipment lifespan, and ensures continuous, reliable production.

How do digital tools continue the legacy of manufacturing pioneers?

Digital tools like CMMS reinforce process clarity, measurement, and continuous improvement while adapting traditional principles to modern industrial challenges.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!