Published: July 28, 2025 | Updated: October 23, 2025

Published: July 28, 2025 | Updated: October 23, 2025

Material Safety Data Sheets (MSDS): Ensuring Chemical Safety and OSHA Compliance

What are Material Safety Data Sheets (MSDS), and why do they matter? In any facility handling chemicals, MSDS play a central role in safety and compliance. From protecting workers to supporting emergency responses, these documents contain vital data. This guide to safer chemical handling through material safety data sheets breaks down the purpose and structure of MSDS and how digital systems assist in their management.

What are Material Safety Data Sheets (MSDS), and why do they matter? In any facility handling chemicals, MSDS play a central role in safety and compliance. From protecting workers to supporting emergency responses, these documents contain vital data. This guide to safer chemical handling through material safety data sheets breaks down the purpose and structure of MSDS and how digital systems assist in their management.

What Is an MSDS and Why Is It Vital for Chemical Safety?

A Material Safety Data Sheet—now more commonly referred to as a Safety Data Sheet (SDS)—details critical safety and handling information about hazardous chemicals. MSDS serve as a key point of reference for employers, technicians, and first responders. Their content describes chemical risks, protective measures, and how to manage exposure.

Each MSDS provides a standardized format to ensure that anyone accessing it—regardless of their location or role—receives consistent and accurate information. Regulatory agencies, such as OSHA, require these documents for all hazardous substances used or stored in the workplace.

Why Material Safety Data Sheets Are Required for OSHA Compliance

MSDS aren't just helpful—they're legally mandated in many jurisdictions. These documents provide transparency and safety across the chemical management process. Several key reasons make MSDS a workplace essential:

- Worker Safety: MSDS outline potential hazards such as toxicity, flammability, or corrosiveness. When workers understand these dangers, they take proper precautions with protective equipment or exposure limits.

- Emergency Readiness: In the event of a spill or fire, emergency personnel can refer to the MSDS to determine containment procedures or first aid measures.

- Regulatory Compliance: Agencies like OSHA require businesses to keep MSDS accessible for every hazardous chemical. Violations can trigger significant penalties.

- Risk Management: Employers gain insight into chemical properties, allowing them to implement safer handling, better ventilation systems, and improved disposal protocols.

Discover how streamlined maintenance processes can elevate production. Learn more.

What Information Is Included in an MSDS?

Each MSDS follows a format that delivers 16 key data points. This structured layout simplifies communication and improves clarity for all involved parties.

1. Identification

This section includes the product name, synonyms, and the CAS number. The CAS (Chemical Abstracts Service) number acts as a global identifier, helping teams avoid confusion when substances have multiple names. The CAS number ensures:

- Precision: Removes ambiguity in identifying substances.

- Standardization: Maintains consistency across countries and industries.

- Compliance: Agencies like the EPA use CAS numbers for regulation.

- Access: Makes it easier to find toxicity data, usage guidelines, and chemical behavior.

2. Hazards Identification

Covers risks such as flammability, reactivity, and health hazards. This helps prevent accidents and improve emergency planning.

3. Composition and Ingredients

Lists chemical ingredients and their concentrations. Transparency here is vital for understanding exposure risks and enforcing safety thresholds.

4. First Aid Measures

Details initial responses for eye contact, inhalation, skin exposure, or ingestion. Quick access to this section can reduce injury severity.

5. Firefighting Measures

Describes extinguishing methods, flammable properties, and protective gear needed during chemical fires. Some substances react violently with water and require specialized suppression tools.

6. Accidental Release Measures

Covers containment and cleanup techniques following a spill. Also includes evacuation guidance and environmental precautions.

7. Handling and Storage

Outlines how to safely store and handle the chemical. Some require temperature regulation, specific containers, or segregation from incompatible materials.

8. Exposure Controls and PPE

Defines permissible exposure levels and what personal protective equipment (PPE) workers should use. Gloves, goggles, and ventilation might all come into play here.

9. Physical and Chemical Properties

Includes boiling point, melting point, pH, flash point, and solubility. These properties help predict how the chemical reacts in various environments.

10. Stability and Reactivity

Describes conditions to avoid (such as heat, pressure, or moisture) and which substances the chemical might dangerously react with.

11. Toxicological Information

Explains short- and long-term health effects of exposure. Includes data on carcinogenicity, reproductive toxicity, and routes of exposure.

12. Ecological Information

Evaluates environmental impact—what happens when the chemical enters waterways, soil, or air. This supports sustainability goals and legal compliance.

13. Disposal Considerations

Details safe methods for disposal, including hazardous waste handling and recycling instructions. Many chemicals require professional waste services.

14. Transport Information

Includes shipping names, hazard classifications, and packaging instructions. Proper transport prevents leaks and legal issues.

15. Regulatory Information

Lists relevant regulations at local, national, and international levels. This may include OSHA's Hazard Communication Standard.

How and Where to Store MSDS for Maximum Accessibility and Safety

MSDS should never be buried in a filing cabinet or locked in an office. Access must be easy and immediate. Digital repositories, physical binders in common areas, and labels near workstations all ensure visibility.

The law requires that employees can retrieve an MSDS for any hazardous material they may encounter—at any time. Accessibility supports rapid response in emergencies and helps reduce liability exposure.

MSDS Compliance Violations: Penalties and Legal Risks

Failure to maintain and display MSDS can bring steep consequences. Regulatory agencies issue citations and fines under standards like the Hazard Communication Standard. Beyond that, companies face lawsuits and reputational damage when employees are harmed due to withheld or missing information.

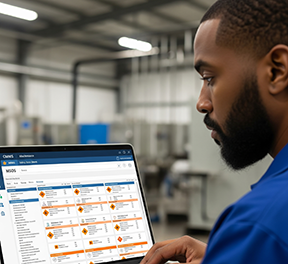

Using CMMS Software to Manage MSDS and Improve Chemical Safety

A computerized maintenance management system (CMMS) makes handling MSDS far more efficient. These systems digitize the process by linking each hazardous material to a central repository of its safety documentation.

A computerized maintenance management system (CMMS) makes handling MSDS far more efficient. These systems digitize the process by linking each hazardous material to a central repository of its safety documentation.

When creating work orders, you can attach the relevant MSDS file, ensuring technicians receive hazard details before stepping on-site. That not only enhances safety—it also simplifies audits and inspections.

Why MSDS Are Essential for OSHA Compliance

Regulators appreciate when documentation is easy to retrieve. A CMMS provides that visibility. With just a few clicks, teams can access records, confirm compliance, and maintain safer workflows.

There's a distinct difference between a facility that manages risk and one that invites it. Understanding the role of MSDS is not an academic exercise—it's a daily necessity. Every safety measure starts with knowledge, and that knowledge begins with proper documentation.

FAQs

What is an MSDS and why is it important for workplace safety?

A Material Safety Data Sheet (MSDS) provides detailed information about chemical hazards, helping workers handle substances safely and comply with OSHA regulations.

How can a CMMS improve MSDS management?

A CMMS like MAPCON allows you to store, organize, and instantly access all your MSDS files digitally, improving compliance and emergency response times.

What information is included in an MSDS?

An MSDS includes chemical identification, hazards, handling instructions, first aid measures, and regulatory data to guide safe use and storage.

Why is OSHA compliance connected to maintaining MSDS?

OSHA requires employers to keep MSDS accessible for every hazardous chemical, ensuring employee safety and avoiding costly penalties.

Where should MSDS be stored for maximum safety?

They should be easily accessible—digitally through systems like MAPCON CMMS or physically in common work areas for quick reference.

What happens if a company fails to maintain MSDS records?

Non-compliance can result in OSHA fines, legal action, and increased risk of workplace accidents or injuries.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!