Published: July 07, 2022 | Updated: October 06, 2025

Published: July 07, 2022 | Updated: October 06, 2025

The Expansive Roles of a Computerized Maintenance Management System

The term "business function" often evokes images of formal gatherings focused on strategic agreements. However, within the context of a Computerized Maintenance Management System (CMMS), "function" describes a set of capabilities that significantly influence various operational facets. This exploration delves into the expansive roles a CMMS provides, drawing insights and expanding upon key areas to illustrate its comprehensive value within a modern organization. These functions extend beyond basic task management, impacting areas such as organization, finance, production, marketing, and even employment dynamics.

The term "business function" often evokes images of formal gatherings focused on strategic agreements. However, within the context of a Computerized Maintenance Management System (CMMS), "function" describes a set of capabilities that significantly influence various operational facets. This exploration delves into the expansive roles a CMMS provides, drawing insights and expanding upon key areas to illustrate its comprehensive value within a modern organization. These functions extend beyond basic task management, impacting areas such as organization, finance, production, marketing, and even employment dynamics.

For further discussion on the following points, read the article at CommercePK.

The Organizing Power of a CMMS

The notion of achieving unified action across numerous elements can feel akin to the challenge of coordinating a multitude of independent entities. In a maintenance environment, supervisors frequently encounter situations demanding meticulous control over diverse activities and resources. The transition from manual methods, such as spreadsheets, to more sophisticated systems became necessary as the complexity of business operations increased. The foundational organization offered by simple spreadsheets proved insufficient to handle the intricacies of modern maintenance demands.

Preventive Maintenance and Structured Data

A Computerized Maintenance Management System serves as a powerful organizer, particularly in the realm of preventive maintenance. Unlike the limitations of spreadsheets, a CMMS features a dedicated PM menu. This allows for the establishment of maintenance cycles, the automatic generation of work orders based on these schedules, and the availability of numerous PM-related reports. The design of this menu promotes structured organization, enabling users to efficiently manage equipment lists, inventory details, and cost center information through logically arranged tabs and options.

Initial PM creation requires minimal input, yet the system allows for extensive detail. Users can incorporate labor specifications (including crews, crafts, shifts, and job steps), material and tool requirements, supplementary attachments for clarity, and much more. These organized PM records offer easy accessibility, with a simple double-click providing comprehensive information.

Work Order Management and Enhanced Tracking

The organization of work orders presents a significant challenge for systems lacking dedicated features. Traditional methods often involve disparate communication channels such as email, text messages, or paper-based notes. A quality CMMS centralizes this process, enabling the creation of work requests—for instance, reporting a potential hazard like a loose light fixture—and the subsequent initiation of formal work orders to address the issue.

Within both work requests and work orders, the system maintains a high degree of organization, allowing for the input of detailed information relevant to each job. This includes work order types, priority levels, site and zone designations, submission dates, and supporting attachments. Beyond creation, the system provides various methods for tracking work orders throughout their lifecycle, even after completion. Given that many maintenance tasks are recurring PMs, the ability to reuse work order templates saves significant time and effort. Furthermore, comprehensive reports ensure ongoing organizational oversight.

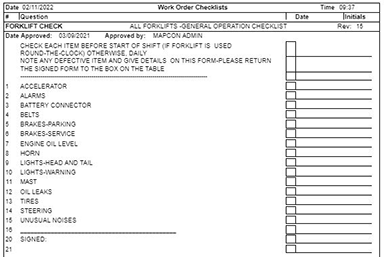

Standardization Through Checklists and Safety Protocols

Standardization Through Checklists and Safety Protocols

Checklists represent a fundamental tool for promoting organization and consistency in maintenance procedures. Rather than relying on individual interpretation, a CMMS allows for the creation of detailed checklists that outline the specific steps required for a task. This is akin to providing detailed job steps, ensuring clarity, and adherence to established procedures. Similarly, the integration of safety procedures within the CMMS contributes significantly to workplace organization and well-being. These can include official regulatory guidelines or facility-specific safety measures, ensuring that crucial safety information is readily accessible when and where it is needed.

Discover how streamlined maintenance processes can elevate production. Learn more.

Integrated Asset, Inventory, and Location Management

Equipment, inventory, and location data are often interconnected within a CMMS, facilitating a cohesive organizational structure. The same principles applied to creating organized PM lists extend to these critical areas. Location management allows for a granular breakdown of facilities, eliminating ambiguity regarding equipment placement or maintenance locations. Inventory management features enable the systematic organization of stockrooms, assigning parts and tools to precise locations such as aisle, shelf, and bin. This level of detail ensures efficient retrieval and reduces the likelihood of misplaced items.

Optimized Maintenance Through Routes and Purchase Order Efficiency

Maintenance routes offer an effective method for organizing recurring maintenance tasks. By defining a sequence of steps, each potentially including checklists or specific jobs, routes eliminate guesswork and unnecessary back-and-forth communication. The management of purchase orders also benefits from the organizational capabilities of a CMMS. Similar to maintenance workflows, the system handles requisitions and purchase orders, as well as the organization of receiving processes and invoice reconciliation. Advanced features may include the ability to create lists of frequently purchased items from specific vendors, simplifying the purchase order creation process and reducing administrative overhead.

Human Resources Organization Within the CMMS

The scope of a CMMS extends beyond physical assets to include the organization of human resources. Employee records can encompass names, titles, contact information, and even educational backgrounds. The system can also track timecards, compensation rates, and work schedules. This centralized management of employee data contributes to overall operational efficiency and facilitates better resource allocation.

The Financial Implications of a CMMS

The financial health of any organization remains a primary concern. Budgets, invoices, recurring expenses, and labor costs collectively influence the overall financial performance. A CMMS provides tools and insights that directly impact these financial aspects.

Labor Cost Tracking and Attainment Analysis

Building upon the HR functionalities, a CMMS allows for the generation of detailed labor reports categorized by various parameters such as craft, shift, crew, route, time off, cost center, and associated equipment. Attainment reports offer valuable insights into the efficiency of labor utilization by comparing scheduled hours against actual maintenance time recorded. Comprehensive Hours Worked Report menus provide numerous ways to aggregate and analyze labor data, supporting informed decision-making regarding resource allocation and cost control.

Cost Center Management and Purchasing Oversight

For organizations with multiple cost centers, a CMMS facilitates the tracking of expenses and activities associated with each. In the realm of purchasing, the system enables the tracking of receipts by category, vendor, due date, and user. Performance reports on vendors can highlight delivery times and other key metrics, aiding in vendor selection and relationship management. The ability to identify past orders and track the status of current orders improves accountability and helps prevent delays.

Project Cost Management

Organizations undertaking large-scale projects, such as facility expansions or new construction, can leverage CMMS software to assist with the financial management of these initiatives. Features may include the ability to track costs associated with specific project phases, labor, materials, and equipment, providing a comprehensive overview of project expenditures.

The CMMS Role in Production Efficiency

While seemingly distinct, a CMMS plays a vital role in enhancing production efficiency. This connection stems directly from the organizational capabilities discussed earlier. When assets and inventory are meticulously managed and when locations and routes are clearly defined, the execution of work orders becomes more efficient. This allows maintenance personnel to dedicate more time to the actual maintenance tasks, including refining time estimates and evaluating the successful completion of work against established goals.

Focus and Measurable Productivity Gains

Improved organization translates directly to an enhanced focus on assigned tasks. This increased focus contributes to measurable gains in productivity. CMMS features such as Issue/Return procedures for tools and the creation of Tool Kits further contribute to operational efficiency by ensuring that necessary equipment is readily available and accounted for. The integration of checklists and safety procedures also plays a role in production by ensuring tasks are performed correctly and safely the first time, reducing rework and potential delays.

Marketing Value Through a CMMS

The connection between a CMMS and marketing might not be immediately obvious, yet a well-implemented system contributes to customer satisfaction and positive brand perception in several indirect ways. Consistent service, well-maintained facilities, and efficient operations all contribute to a positive customer experience.

Scalability, Support, and Feature Innovation

From a vendor perspective, the value proposition of a CMMS includes scalability to meet evolving client needs, excellent customer support, and the continuous development of new and unique features. For end-users, the system's ability to track vendor performance, including discounts for bulk orders, provides tangible value. The wealth of reports and data generated by a CMMS also serves as a significant asset in satisfying audit requirements, enhancing trust and credibility.

Mobile Accessibility and Enhanced Responsiveness

The availability of a mobile application for a CMMS offers substantial marketing benefits by enabling quicker response times and more efficient service delivery. Equipping maintenance personnel with mobile access allows them to receive and update work orders remotely, improving communication and reducing delays. This efficiency translates to greater customer satisfaction and a more positive perception of the organization's responsiveness.

The Impact of a CMMS on Employment Dynamics

A quality CMMS fosters a sense of teamwork and clarity within an organization. By effectively dispatching work orders to individuals or teams, the system ensures that everyone understands their responsibilities and the scope of the work required.

Teamwork and Inclusive Participation

Even employees who are not direct users of the CMMS can benefit from its implementation. Consider the example of a non-user identifying a maintenance issue. A well-designed CMMS should provide accessible mechanisms for reporting such issues, such as a simple HTML link that supervisors can share via email. Once the information is submitted through this link, it enters the system for review and action, ensuring that all employees can contribute to the maintenance process, fostering a sense of shared responsibility and inclusion.

The various functions illustrate the extensive benefits a CMMS offers across numerous organizational domains. When evaluating such a system, considering how it aligns with specific facility management needs is crucial. Investigating the capabilities of platforms like MAPCON can provide valuable insights into how these functions translate into tangible improvements for your operations. Exploring these possibilities represents a proactive step toward enhanced efficiency and control.

FAQs

What roles can a CMMS play in an organization?

A CMMS supports organization, finance, production, HR, and even marketing by streamlining maintenance and operational processes.

How does a CMMS improve preventive maintenance?

It automates scheduling, generates work orders, and keeps detailed records, ensuring tasks are completed consistently and on time.

Can a CMMS help manage finances?

Yes, CMMS tools track labor costs, budgets, vendor invoices, and project expenses, giving businesses better financial control.

Does a CMMS improve production efficiency?

By organizing assets, inventory, and work orders, a CMMS reduces downtime and boosts overall productivity.

How does mobile access enhance CMMS use?

Mobile apps allow technicians to receive, update, and close work orders remotely, improving responsiveness and service speed.

What impact does a CMMS have on employees?

A CMMS fosters teamwork by clarifying responsibilities, tracking progress, and even allowing non-users to report maintenance issues.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!