Published: January 09, 2025 | Updated: October 20, 2025

Published: January 09, 2025 | Updated: October 20, 2025

Success With Preventive Maintenance Checklists

Actually, what this article will present will not only fulfill preventive maintenance (PM) checklists, but those for other repairs. Checklists provide step-by-step instructions. Some maintenance tasks require a certain order of completion. With a checklist, you help ensure the technician completes all steps.

Actually, what this article will present will not only fulfill preventive maintenance (PM) checklists, but those for other repairs. Checklists provide step-by-step instructions. Some maintenance tasks require a certain order of completion. With a checklist, you help ensure the technician completes all steps.

Read further for:

Many of us use checklists every day. Home projects include setting up a backyard swimming pool or swing set. Homeowners build furniture and model cars from kits. Each of those projects has a set of step-by-step instructions.

Benefits of Using Maintenance Checklists

In the workplace, technicians follow checklists to:

- Ensure quality work. No cutting corners.

- Completion of the job. Again, no skipping procedures.

- Safety. Part of the checklist might include protocols before, during, or after a step to reduce safety risks.

- Documentation. Filling out a checklist gives supervisors and others an account of the job. However, a spot-check review should occur. You don't want a worker not doing the job but sitting in his office just checking off the boxes.

- Help for new workers. All workers don't share the same skills. A new team member may need to "get up to speed" on some of the jobs. A checklist helps integrate the new person into the job.

- Standardization. You don't want different workers doing the same job in different ways. A checklist keeps everything uniform.

- Efficiency. You've provided the steps that result in efficiency. This saves time with the worker wondering what comes next.

- Troubleshooting. If problems occur, you have a better idea of the problem, cause, and solution.

- Improvement. With a checklist and reviews, you form better methods.

Types of Maintenance Checklists

You can use various names for these. Acceptance/rejection and procedural. Simple and advanced.

Simple: These checklists contain boxes the technicians check when they complete a step. These common types make for better efficiency because the worker just follows the list.

Example: Forklift inspection

- Accelerator

- Alarms

- Battery connector

- Belts

- Brakes-parking

- Engine Oil Level

- Horn

- Lights

- Etc.

Each of these has a box to check after the worker completes the inspection of that part.

Advanced: These checklists require information for many or all instructions. Examples include:

- What's the temperature reading on the machine?

- What's the depth of fluid in the basin?

- Does PSI fall within the tolerable range?

Other questions or conditions to answer depend on the industry and company. The answers may dictate the next step. If this, then that.

Advanced example: Equipment Audit Rating

- Are the start and stop controls clearly marked?

- Are other operating controls clearly marked?

- Is the equipment used in accordance with the MFG instructions?

- Are all dangerous parts of the machinery guarded?

While these and others require a yes/no answer, you could have information requiring actual readings as noted above.

Discover how streamlined maintenance processes can elevate production. Learn more.

Steps for Creating a Successful Preventative Maintenance Checklist

Let's highlight seven aspects to keep in mind.

- Safety. This should top the list. You pay attention to safety and have the technician follow. Steps should include any protocols to ensure safety for the asset and the worker.

- This includes PPE gear, lock-out/tag-out, and cleaning.

- Pay attention to the order of steps. Remember the benefit from above. Standardization helps to create efficiency.

Follow this guide throughout the steps. Safety, clean, adjust, inspect. replenish, replace, rebuild, safety.

- Attachments. Attach documentation for regulations or protocols. Images and URLs for video instructions help guide the worker to understand the job.

- Keep it simple. This does not suggest you stick to the simple type of checklist. This refers to the instructions. No need for encyclopedia entries for each step.

- Time. A suggestion to add an estimated time for each step and/or the entire job might benefit workers.

Best Practices for Using Maintenance Checklists

Where should you use checklists? Any job where you deem order important. For instance, cleaning a parking lot leaves room for options. Rebuilding an intricate piece of machinery doesn't.

Does this mean that during the aforementioned example of the forklift inspection, the technician must go step by step? Perhaps that example leaves a little leeway. As you'll see, following the list increases the chances for efficiency.

How to use a checklist?

- Read each step completely. This sounds obvious but how many times have you skipped ahead because you "think you know it"?

- Follow the instructions in order. Again, obvious, but skipping increases the chances of missing something.

- Take time to mark off the box or input the answer before you move to the next step. You need to resist the temptation to just move on and come back later to check off. You might skip a step. You might not remember the information to input.

Take a few seconds to complete and check the box. Every time. Each step.

- Review your work. Either as you move through the steps or after completing the job.

- Double check. And maybe triple-check. Not only your work but that you've completed each step and mark it.

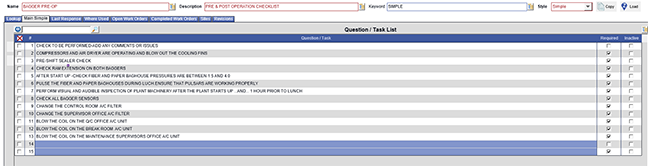

Enhancing Checklist Efficiency with CMMS Software

With quality software, you organize your assets, inventory, PMs, and work orders. Look for a system that incorporates checklists. Many jobs require these lists every time. Therefore, you create your list and attach it to the PMs and work orders.

As an admin, you review these lists with works, discussing comments and feedback. That way, you improve on the operations. Maybe, the list needs adjusting.

Many times, you'll need to inactivate one of the steps. However, you'll want the option to require it in the future.

The Importance of Maintenance Checklists for Preventative Success

We follow instructions for home projects. Why should you act any differently in the workplace? Review the safety reasons. They hold for both home and work.

You make lists for groceries and supplies when shopping. In your company, you can include which parts to use for each step.

Make these lists part of your maintenance operations. Invest in Mapcon's superior CMMS for further success. 800-922-4336

FAQs

What is the primary benefit of using preventive maintenance checklists in the workplace?

Checklists ensure quality work, job completion, and adherence to safety protocols by providing step-by-step instructions that prevent a technician from cutting corners or skipping procedures.

What is the most important element that should top a PM checklist?

Safety should top the list, with steps including necessary protocols such as the use of PPE gear and lock-out/tag-out procedures to ensure the safety of the worker and the asset.

How does a maintenance checklist contribute to standardization?

A checklist helps to standardize maintenance tasks by ensuring that different workers perform the same job in a uniform manner, following a consistent order of completion.

How can a CMMS, like MAPCON, enhance the efficiency of maintenance checklists?

A CMMS allows you to create and attach checklists directly to PMs and work orders, helping to organize the task and enabling admins to review feedback and continuously improve the procedures.

Besides ensuring completion, how do checklists benefit new maintenance workers?

Checklists help integrate new team members by providing clear, step-by-step guidance on various jobs, allowing them to quickly "get up to speed" on required procedures.

What should a technician resist the temptation to do when using a maintenance checklist?

A technician should resist the temptation to move on and check off boxes later, as they risk skipping a step or forgetting important information they need to input.

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!