Published: September 09, 2025 | Updated: October 24, 2025

Published: September 09, 2025 | Updated: October 24, 2025

Top Work Order Software Features That Maximize Maintenance Efficiency

Choosing the right work order software can mean the difference between scheduled control and reactive chaos. While some teams still rely on emails and spreadsheets, today's Computerized Maintenance Management Systems (CMMS) deliver far more power and flexibility. When reviewing top work order software must-haves, smart facilities dig into features that improve visibility, communication, and maximize maintenance efficiency.

Choosing the right work order software can mean the difference between scheduled control and reactive chaos. While some teams still rely on emails and spreadsheets, today's Computerized Maintenance Management Systems (CMMS) deliver far more power and flexibility. When reviewing top work order software must-haves, smart facilities dig into features that improve visibility, communication, and maximize maintenance efficiency.

User-Friendly Interface That Reduces Friction

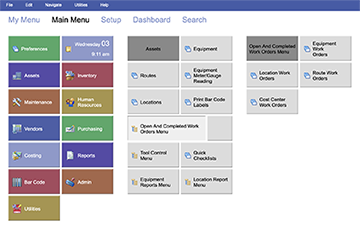

Technicians and supervisors rely on software daily. If the interface causes delays or confusion, productivity drops fast. CMMS platforms must feature clean layouts, clearly defined tabs, and consistent module structures. Navigation should mirror user workflows—not confuse them. If a technician opens the inventory module, they shouldn’t sift through irrelevant asset data. The main dashboard must highlight frequently used actions like new work orders, parts requests, or KPI dashboards.

A quality CMMS has organized screens to reduce training time and increase adoption. Logical placement of fields and consistency in design across modules helps workers trust the tool instead of working around it.

Customizable Work Order Templates

Work order fields should adapt to operations—not the other way around. Templates that allow admins to show, hide, or rename data fields save time and reduce errors. For example, a manufacturing plant may want to add fields for compliance inspection codes, while a water utility might focus on location tags and crew assignments.

Look for easy customization of work order screens and the addition of drop-down lists or checkboxes. This flexibility supports data standardization across teams while ensuring each work order captures the required details for audits and analysis.

Scheduling Tools That Power Proactive Maintenance Management

A strong CMMS includes drag-and-drop scheduling and automated dispatch notifications. Maintenance planners benefit from visual calendars that map technician availability, upcoming preventive tasks, and equipment downtime windows. Once assigned, technicians receive email or mobile alerts with full work order details.

This type of task assignment workflow ensures timely maintenance and provides a historical log of completed, delayed, and backlogged jobs. Over time, that record supports more accurate forecasting and labor planning. Companies in transit, healthcare, and utilities all rely on these capabilities to hit service level agreements.

Discover how streamlined maintenance processes can elevate production. Learn more.

Performance History and KPIs

Work order software should track performance, not just tasks. Maintenance leaders need access to metrics like time-to-completion, response time by priority, mean time between failures, and technician utilization. Built-in reporting tools and KPI dashboards help identify problem areas early—before downtime escalates.

Systems like MAPCON offer specific work order KPI reporting,, including metrics outlined in this article.

Permission Control Features to Support Smarter Maintenance Management

Not every employee should have the same work order privileges. CMMS platforms must support user roles with customized access, including who can create, edit, approve, or escalate work orders. Priority levels must follow a clear framework that prevents low-impact tasks from disrupting critical work.

Standardizing priority levels, such as a 1–5 scale (1 = immediate danger, 5 = routine service), ensures consistent expectations across shifts and teams. Training must reinforce the guidelines so that requests reflect the real urgency of the job.

Integration with Third-Party Systems

Maintenance doesn’t happen in isolation. Work order software must integrate with accounting, ERP, HR, and purchasing systems to reduce duplicate data entry and link financials with asset performance. Of course a system such as MAPCON has purchasing and HR modules available without integration.

Mobile Access Extends Field Capabilities

Work rarely stays in the office. Mobile CMMS access allows technicians to log jobs, view asset histories, and scan barcodes directly from their phone or tablet. In industries like water treatment, mining, and transit, this mobile capability eliminates delays and supports real-time updates from the field.

Barcode scanning links equipment data and inventory levels. This avoids unnecessary return trips or delays while confirming parts availability. In remote environments, a mobile CMMS reduces downtime by enabling faster diagnosis and documentation.

Custom Reporting to Improve Maintenance Management Decisions

Effective maintenance requires data visibility. Reports must reflect variables like location, equipment type, assigned crew, and date range. Whether comparing the maintenance cost of two compressors or tracking completion rates by shift, custom reports provide the insights leadership needs.

Multi-site organizations benefit from site-specific reporting options. With filters for craft, equipment type, or open vs. closed orders, decision-makers can uncover trends and adjust resource allocation based on real performance data.

Integrated Inventory Controls

No part, no fix. Work order software must include inventory tracking to ensure parts and supplies align with job needs. Clear bin location, reorder levels, and issuance tracking help prevent costly delays. CMMS platforms with barcode integration enhance accuracy and audit readiness.

Some systems enable issue/return workflows so supervisors track part usage. Maintenance teams using inventory-linked work orders cut guesswork and limit unplanned equipment downtime due to missing parts.

Linking Work Orders to Asset History for Better Maintenance Efficiency

Work orders shouldn’t exist in a vacuum. Link each one to the appropriate asset to build a complete service history. Include fields for usage hours, mileage, temperature readings, and other condition-based indicators. This alignment improves preventive maintenance and asset replacement planning.

For example, fleet operations often rely on hour-based maintenance cycles. Linking those hours to the assigned work order ensures no task slips through due to inaccurate logs or miscommunication.

Communication and Documentation Tools

Standardizing how work gets described reduces errors and boosts compliance. Each work order should capture task type, location, tools needed, safety requirements, attachments, and comments. MAPCON allows technicians to submit “after-the-fact” work orders for unplanned work performed during other tasks.

Including links to manuals, safety datasheets, or images supports job clarity and reduces training time. Comment fields or activity logs help track updates and improve shift-to-shift communication.

Procurement Features That Support Streamlined Maintenance Management

When CMMS tools support procurement, purchasing and maintenance departments align better. Teams can generate purchase requests directly from work orders, match vendor quotes, and reconcile shipments—all in the same system. That creates audit-ready trails and faster part availability.

Standardized PO formats and stored vendor profiles help streamline vendor management while reducing errors in part specifications or delivery timelines.

Scalable Work Order Software That Grows with Your Maintenance Needs

Business needs shift. CMMS solutions must scale based on user count, number of sites, and added capabilities like barcode modules or API integrations. Companies may start with basic scheduling but expand into predictive analytics or IoT-based maintenance. The software must grow with them.

Providers like MAPCON build modular platforms. Customers activate new features only when needed, avoiding unnecessary costs or clutter. If a team adds a new facility or maintenance discipline, that same system can support the shift.

Invest in Long-Term Fit, Not Just Features

Software becomes a true partner when it fits how teams think and work—not just what they need today. The right CMMS aligns with culture, job complexity, and reporting requirements. Instead of chasing features, maintenance leaders should evaluate how the system strengthens communication, accountability, and planning over time.

FAQs

What is the main advantage of using work order software over spreadsheets?

Work order software, like a CMMS, provides far greater power, flexibility, and control by centralizing data and moving maintenance from reactive chaos to scheduled control.

What CMMS feature is essential for proactive maintenance management?

Effective scheduling tools are essential, featuring automated dispatch notifications and visual calendars that map technician availability and upcoming preventive tasks.

Why is linking work orders to asset history important?

Linking work orders to asset history helps build a complete service record, which is vital for improving preventive maintenance planning and informed asset replacement decisions.

How does a quality CMMS improve technician training time?

A quality CMMS uses an organized, user-friendly interface with logical field placement and consistent design, which significantly reduces the amount of time needed for technician training.

How does MAPCON CMMS help maintenance leaders track performance?

Systems like MAPCON provide access to key performance indicators (KPIs) through built-in reporting to track metrics like time-to-completion, mean time between failures, and technician utilization.

What is the role of mobile access in maximizing maintenance efficiency?

Mobile CMMS access, often paired with barcode scanning, allows technicians to log jobs, view asset histories, and make real-time updates from the field, eliminating delays and return trips.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!