Published: January 13, 2022 | Updated: October 01, 2025

Published: January 13, 2022 | Updated: October 01, 2025

Visual Integration: Supercharge Your CMMS with Images and Safety Information

Ever struggled to describe a part, resorting to vague gestures and imprecise language? This common scenario wastes valuable time and increases the risk of ordering the wrong component, especially within the critical operations of a plant. This article explores how to supercharge your Computerized Maintenance Management System (CMMS) with images and safety information.

The Power of Visuals in Maintenance Management

Imagine a maintenance technician encountering an unfamiliar piece of equipment. Instead of deciphering potentially outdated or unclear text descriptions, they can instantly access a detailed image or even a short video demonstrating the part's function. This immediate visual clarity eliminates ambiguity and accelerates the identification process. Attaching images to inventory items within your CMMS provides a definitive reference point for all personnel, from seasoned veterans to new hires. This visual catalog ensures everyone operates with the same understanding, minimizing errors during part retrieval and work order execution.

Boosting Productivity and Efficiency

When work orders include clear images of the required parts or the equipment needing attention, technicians spend less time trying to understand the task. They arrive at the job site with a precise understanding of what’s needed, leading to faster repairs and reduced downtime. Consider the impact on planning: maintenance teams can use these visuals to accurately assess job requirements, allocate the correct tools and personnel, and pre-stage necessary components. This proactive approach significantly improves scheduling accuracy and minimizes disruptions.

Furthermore, integrating images into purchase orders drastically reduces the chances of receiving incorrect parts from vendors. A picture speaks volumes, leaving no room for interpretation errors based on potentially confusing textual descriptions alone. This accuracy saves time, money spent on returns and restocking, and the frustration of dealing with mismatched components.

Real-World Applications

Consider a manufacturing plant where a specific sensor on a critical production line malfunctions. A technician can use a mobile CMMS application to take a picture of the damaged sensor and attach it directly to the emergency work order. This image immediately communicates the exact nature of the problem to the maintenance team and any external vendors involved. The correct replacement part gets identified and ordered swiftly, minimizing production delays. In another scenario, a facility manager can attach images of specific valve types to their corresponding inventory records. When a work order requires replacing a particular valve, the technician can visually confirm they have the correct component before starting the work, preventing costly mistakes.

Prioritizing Safety with CMMS Integration

Beyond part identification and work order clarity, a CMMS offers a vital platform for integrating safety protocols and information directly with assets and tasks. Attaching relevant safety documents ensures that personnel have immediate access to crucial guidelines before commencing any maintenance activity.

Safety Protocols and Procedures

Imagine a scenario where a specific piece of machinery requires a unique lockout/tagout procedure. By attaching a document outlining this exact procedure to the asset record in the CMMS, any technician assigned to work on that machine can easily review and adhere to the necessary safety steps. This direct access to protocol information reduces the risk of accidents and promotes a safer working environment. Regular reviews and updates of these attached safety documents ensure that the latest guidelines are always readily available.

Safety Data Sheets (SDS)

For any chemicals or hazardous materials used in maintenance processes, attaching the corresponding Safety Data Sheets (SDS) to relevant equipment or inventory items is paramount. Technicians can quickly access information on potential hazards, handling precautions, first aid measures, and disposal guidelines directly within the CMMS. This immediate availability of SDS information is crucial for preventing accidents, responding effectively to spills or exposures, and complying with safety regulations. Regularly updating SDS documents within the system ensures the accuracy and relevance of this critical safety information.

Leveraging Video Instructions and Clarification

Sometimes, a static image or a written document cannot fully convey the intricacies of a particular maintenance task or the proper use of a specific part. In such cases, the ability to attach weblinks to video demonstrations or instructional content within the CMMS offers significant advantages.

Enhanced Understanding and Training

Consider a complex calibration procedure for a sensitive instrument. Instead of relying solely on a written manual, a technician can access a short video demonstrating each step of the process. This visual guidance can significantly improve understanding, reduce the learning curve for new personnel, and minimize the risk of errors during execution. Similarly, videos showcasing the correct installation or removal of intricate parts can prevent damage to equipment and ensure proper functionality.

External Resources and Expert Knowledge

Attaching weblinks to manufacturer-provided video tutorials or expert demonstrations can provide technicians with access to a wealth of knowledge beyond internal documentation. This direct connection to external resources can be particularly valuable for troubleshooting complex issues or learning about new equipment and procedures. Regularly curating and updating these linked resources ensures that technicians always have access to the most current and reliable information.

Industry Examples of CMMS with Attachment Capabilities

Numerous industries already benefit from CMMS solutions that incorporate attachment functionalities. In the aerospace industry, technicians can access detailed diagrams and schematics of aircraft components directly through their mobile CMMS devices during maintenance checks. Hospitals utilize CMMS with image attachments to accurately identify medical equipment requiring repair and to provide visual aids for biomedical technicians. Manufacturing plants across various sectors leverage these features for efficient inventory management, streamlined work order processes, and enhanced safety compliance. The ability to attach visual and informational resources has become a standard expectation in modern maintenance management.

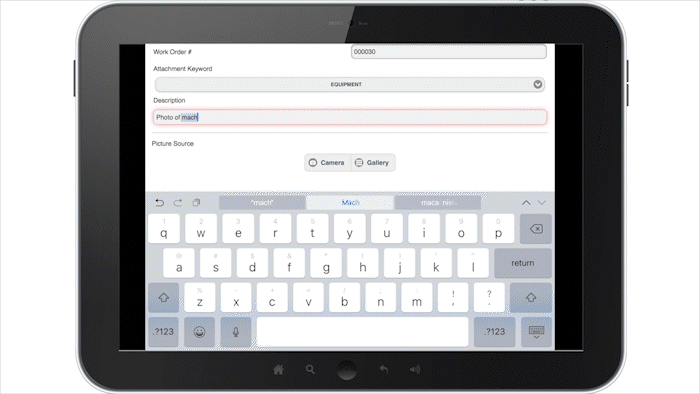

Mapcon Technologies: An Example

Mapcon Technologies, as mentioned in the referenced text, integrates the option for attachments across various modules, including inventory lists, work orders, and purchase orders. Their mobile app further simplifies the process by allowing users to directly upload images from their devices, eliminating the need for cumbersome file transfers. While attachments may not appear on printed orders, they serve as invaluable digital references for technicians and other personnel. Mapcon's implementation and training services assist organizations in effectively leveraging these features to minimize confusion and optimize their maintenance operations.

Implementing Attachment Capabilities and Best Practices

Successfully integrating image and document attachments into your CMMS requires a well-defined strategy and adherence to best practices. Establish clear guidelines for the types of attachments to include for different asset types and work order scenarios. Encourage users to provide high-quality images and ensure that attached documents are relevant and up-to-date. Regularly review and manage your attached files to prevent clutter and maintain system performance. Provide adequate training to all users on how to effectively utilize the attachment features within the CMMS workflow.

Considerations for Video Integration

When incorporating video links, prioritize reliable sources and ensure the content is accurate and relevant. Regularly check the links to confirm they remain active. For internal video creation, keep videos concise and focused on specific tasks or procedures. Establish a system for organizing and managing your library of video resources.

Maintaining Data Integrity and Security

Implement appropriate security measures to control access to attached files and prevent unauthorized modifications. Regularly back up your CMMS data, including all attachments, to ensure business continuity in case of system failures. Adhere to any relevant data privacy regulations when storing and managing sensitive information.

The integration of visual aids and safety information within a CMMS transcends mere convenience; it represents a fundamental shift towards clearer communication, safer practices, and more efficient operations. Embracing these capabilities allows organizations to move beyond ambiguous descriptions and unlock a new level of precision in their maintenance management efforts.

FAQs

What is the benefit of adding images to equipment in a CMMS?

Adding images eliminates ambiguity, accelerates part identification, and ensures all personnel have a clear, definitive reference point.

How does a CMMS enhance safety protocols?

A CMMS allows for the direct attachment of crucial safety information, like lockout/tagout procedures and Safety Data Sheets (SDS), to asset records for immediate access.

Can a mobile CMMS application help with work orders?

Yes, a mobile CMMS application enables technicians to take and attach pictures of damaged parts directly to emergency work orders, speeding up communication and resolution.

How does using images in purchase orders improve efficiency?

Integrating images into purchase orders significantly reduces the chance of receiving incorrect parts from vendors, saving time, money, and frustration.

What is the advantage of attaching videos or weblinks in a maintenance system?

Attaching videos or weblinks provides enhanced visual guidance and training for complex procedures, reducing the learning curve and minimizing the risk of errors.

How does MAPCON CMMS support visual integration?

MAPCON CMMS integrates attachment options across various modules, including inventory and work orders, and its mobile app simplifies uploading images directly from user devices.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!