Published: June 10, 2025 | Updated: October 23, 2025

Published: June 10, 2025 | Updated: October 23, 2025

Work Orders vs. Purchase Orders: What's the Difference

What are the differences between work orders and purchase orders? Each represents a fundamental document within an organization. Each serves a specific purpose in the operational framework. While often interconnected, they have different processing and information.

This article will discuss each document, the information contained within each, its relevance to a maintenance department and the company in general, and how a computerized maintenance management system handles both.

What Is a Purchase Order (PO)? A Procurement Essential

As the buyer, you send this document to the seller, authorizing the purchase of specific goods or services. It outlines the terms and conditions of the transaction and serves as a legally binding agreement between the parties.

What Information Does a Purchase Order Include?

What information do you include in the PO? A lot of this will depend on the industry, the company, and the items/services you purchase. However, commonalities run through many POs.

- Supplier identification. Name, address, phone, number, fax, email, contact person. All of these basic pieces of data start the process.

- Itemized list. What are you buying? Stock? Supplies? You'll need an identifiable description. This could mean a part number or a manufacturer number. If you contract a service, then you'll need the relevant information. This could refer to a cleaning service and the scheduling of the service.

- Quantities. Precise number of items or units. Or you might contract the number of times you want the service. For instance, you schedule a monthly cleaning service for an annual period.

- Pricing. Agreed-upon costs for each item or service.

- Payment terms. Stipulated payment methods and due dates. You might have a thirty-day period in which to pay. You may have a pay-on-delivery contract. How do you pay? Certified check? Online? Cash? Sometimes, you might purchase from overseas. Will you have to convert the payment into local currency? While you would have worked out these arrangements beforehand, you'll want them on the PO for verification. This information also includes billing information. Sometimes, the accounts payable department resides at a different address from where you receive the goods.

- Shipping instructions. Specifies delivery location and method. How will the seller deliver the items? Planes, trains, or automobiles? Or the postal service? What's the expected delivery date?

- Forms. Will you have a standardized form for the PO?

- Attachments. If you purchase through a CMMS, you might add images of the items you want. This adds better clarity to the purchase agreement.

What Is a Work Order (WO)? A Task Execution Document

Let's switch to a work order. This specifies a task or job for someone to complete. It serves as a directive to employees or contractors, outlining the work, necessary resources, and expected completion time.

Key Elements of a Work Order in Maintenance

Key elements of a work order include:

- Type. For instance, maintenance work orders may have different types of jobs. Repair. Overhaul. Corrective. Preventive maintenance. Showing the type of job starts the technician off on the correct path.

- Priority level. Indicates the urgency of the task. Of course, you want to tend to emergencies first. Priorities also help who schedules the jobs. Knowing you can put off a job for a future date helps efficiency.

- Asset. What's being worked on? A vehicle? A conveyor? A forklift? Parking lot? The administration building's roof? You should specify the asset needing attention.

- Location. Specifies the worksite or area. Is this on the main floor? A hallway? The breakroom? Will the maintenance worker travel to the back part of the property to deal with damage caused by trees? Once again, knowing the location of the problem helps to organize the scheduling.

- Task description. Clear and concise explanation of the work required. Part of this might include an estimated time for completion. You can add checklists for either a specific order of job steps or to gather pertinent information for documentation. You can provide safety protocols or video instructions.

- Required materials or equipment. What parts, tools, and supplies will the technician need? With a CMMS, you might have a bill of materials. This way, the technician doesn't have to guess. With locations for the inventory, you save search time, and the worker moves to "wrench time" faster.

- Assigned personnel. Identifies the individuals responsible for completing the task. Check the schedule for labor availability. Also, you specify who does the work. A solo technician? A crew, a specialized craft, or a shift?

Discover how streamlined maintenance processes can elevate production. Learn more.

How Work Orders and Purchase Orders Work Together

While distinct in purpose, purchase orders and work orders often interact within an organization. For example, a work order to repair equipment might necessitate a purchase order for replacement parts. This interdependence highlights the importance of efficient management and integration of these documents.

Using a CMMS offers connections between the two. For instance, MAPCON gives you the option of adding a work order to the purchase order. This will help when you receive the items.

On the other hand, when creating a work order, you can add a purchase order. What does this mean? You have two options. You can add an existing PO or you can create a PO right from the work order!

How Work Orders and Purchase Orders Support Maintenance

What does all this do for a maintenance department? It brings better organization to the planning and scheduling. Assets need maintenance. To do this, technicians need parts. The company purchases parts from selected vendors.

So, while the documents might contain different information, you can see the connections.

Having proper information in both brings clarity to employees. Specific items and relevant information help avoid delays in receiving. Clear descriptions in the WO keep the technician productive.

Work orders direct resources and efforts toward addressing equipment failures, preventive maintenance, and facility upkeep. Purchase orders, in contrast, support the maintenance function by ensuring the availability of necessary parts, tools, and supplies.

At the organizational level, purchase orders contribute to cost control, supplier relationship management, and inventory optimization. Work orders, on the other hand, facilitate asset management, service level agreements, and overall operational efficiency.

Use CMMS Software for Efficient Work and Purchase Order Management

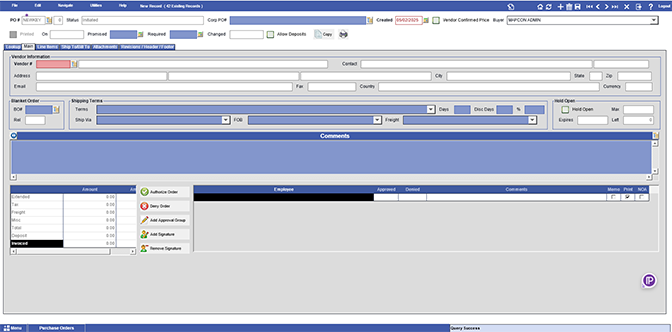

I mentioned CMMS software earlier. This system really brings the organization to your company. You'll have separate areas for work order management and purchase order creation.

Review all of the information needed. You'll find all of those data fields and more in each menu item.

A CMMS offers plenty of reports for each category. That way, you'll have maintenance and labor history, inventory usage, and how well your vendors did. For instance, do they have a high on-time delivery percentage? Do they offer discounts for larger or multiple shipments?

Understanding the differences between work and purchase orders helps your company succeed in multiple areas. However, understanding the connection between them brings operations together.

Know, too, that a maintenance department can use a CMMS for both types of orders. However, if you have a separate purchasing department, it, too, can use the same system as maintenance.

For the best system, contact MAPCON at 800-922-4336. Ask for a free demonstration of the WO and PO menus.

FAQs

What is the difference between a work order and a purchase order?

A work order outlines a task to be completed, while a purchase order authorizes the acquisition of goods or services needed to complete tasks.

What information is included in a purchase order?

A PO typically lists supplier details, items or services, quantities, pricing, payment terms, shipping instructions, and any attachments for clarity.

What details are essential in a work order?

A work order includes the task type, priority, asset, location, description, required materials, and assigned personnel.

How do work orders and purchase orders interact in maintenance operations?

Work orders often generate purchase orders for needed parts, and POs can be linked to WOs to ensure timely resource availability.

How can a CMMS streamline work order and purchase order management?

A CMMS centralizes both orders, allows linking WOs to POs, tracks inventory, schedules tasks, and generates reports for better organization.

Why is using MAPCON’s CMMS beneficial for handling WOs and POs?

MAPCON’s CMMS integrates work and purchase orders, simplifies task and procurement management, and provides detailed reporting to improve maintenance efficiency.

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!