Published: October 06, 2025 | Updated: October 06, 2025

Published: October 06, 2025 | Updated: October 06, 2025

Intermittent Failure and Asset Breakdowns: A Guide to Smarter Asset Management

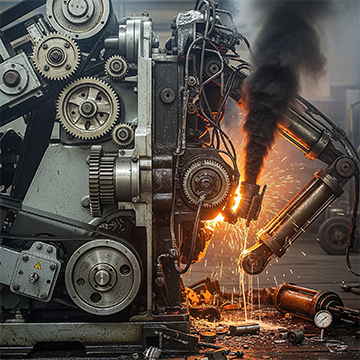

In the world of industrial and business operations, the reading of a discussion entitled "Intermittent Failure: The Silent Threat to Operations" resonates deeply with anyone who manages physical assets. These unpredictable breakdowns are a perplexing and costly problem. Unlike a catastrophic failure with a clear cause, an intermittent failure disappears as quickly as it appears, often leaving maintenance teams scratching their heads. This article delves into the nature of intermittent failure, the benefits of tracking it, the challenges it presents, real-world examples, and the critical role a Computerized Maintenance Management System (CMMS) plays in mitigating its impact.

In the world of industrial and business operations, the reading of a discussion entitled "Intermittent Failure: The Silent Threat to Operations" resonates deeply with anyone who manages physical assets. These unpredictable breakdowns are a perplexing and costly problem. Unlike a catastrophic failure with a clear cause, an intermittent failure disappears as quickly as it appears, often leaving maintenance teams scratching their heads. This article delves into the nature of intermittent failure, the benefits of tracking it, the challenges it presents, real-world examples, and the critical role a Computerized Maintenance Management System (CMMS) plays in mitigating its impact.

An intermittent failure describes a fault or malfunction in an asset that occurs sporadically and without a predictable pattern. It is an inconsistency, a hiccup in performance that doesn't always repeat itself during a diagnostic test. For example, a machine might stop working for a few minutes, then restart and run perfectly for hours or even days. Technicians often face the frustrating "no fault found" scenario, as the issue vanishes before they can isolate the cause. These failures often stem from a range of issues, including loose connections, overheating components, software glitches, or environmental factors like vibration or humidity.

Tracking Intermittent Failures to Prevent Costly Asset Breakdowns

Tracking these unpredictable failures is essential for maintaining operational stability and efficiency. A proper tracking system offers several benefits. It helps maintenance teams identify patterns that aren't obvious from a single event. For instance, a series of seemingly unrelated brief shutdowns might all happen on Tuesdays, pointing to a potential issue with a specific process or operator. This data also allows a business to move from reactive to proactive maintenance. Instead of simply reacting to each failure, a company can use the collected information to schedule preventive maintenance tasks. This approach reduces unplanned downtime, extends the life of assets, and prevents minor issues from escalating into major, costly breakdowns.

The Challenges of Managing Unpredictable Failures

Dealing with intermittent failures presents unique challenges that traditional maintenance practices often fail to address. A primary challenge is the difficulty in diagnosis. Technicians cannot fix a problem they can't replicate. They might spend hours or even days trying to recreate a fault, leading to significant labor costs and wasted time. This can cause frustration and low morale among maintenance staff. Another challenge is the impact on production. While a single intermittent failure might only cause a brief delay, a series of them can cripple a production line. The cumulative effect of these small stops can be as damaging as a major breakdown. Furthermore, the unpredictable nature of these failures makes it difficult to plan for repairs, leading to scheduling conflicts and delays in other maintenance activities. A third challenge is the cost. The time spent on diagnostics, the potential for lost production, and the eventual need for a more significant repair all contribute to a higher cost of ownership for assets with these issues. Without a structured system for tracking, these costs can spiral out of control.

Discover how streamlined maintenance processes can elevate production. Learn more.

Using a CMMS to Track Intermittent Failures

A Computerized Maintenance Management System (CMMS) is an invaluable tool for managing the complex problem of intermittent failure. A CMMS acts as a central repository for all maintenance-related data, providing a structured approach to a seemingly random problem.

Centralized Data and Work Order History

A CMMS provides a centralized database where every work order, repair, and incident gets logged. When a technician responds to an intermittent failure, they create a detailed work order, noting the time, date, symptoms, and any observations. This data then becomes a historical record. Over time, this history builds a comprehensive picture of an asset's performance. The system can then show if similar issues have happened before, even if the individual events seemed unrelated. This historical data is crucial for identifying repeating patterns that a human might miss.

Tracking Equipment Readings and Work Order History

A CMMS provides a centralized database where every work order, repair, and incident gets logged. When a technician responds to an intermittent failure, they create a detailed work order, noting the time, date, symptoms, and any observations. This system also allows for the manual input of equipment readings from sensors, meters, and gauges. Technicians regularly record values like temperature, vibration levels, pressure, or run-time hours directly into the CMMS. This collected data then forms a crucial historical record. Over time, this history builds a comprehensive picture of an asset's performance. The system can then show if similar issues have occurred before, even if individual events seemed unrelated. This historical data is crucial for identifying repeating patterns that a human might miss. For example, a series of brief shutdowns might consistently follow a period where a specific pressure gauge reading exceeded its normal range, indicating a subtle underlying issue. A CMMS's capacity to track manually entered equipment readings significantly contributes to proactive maintenance. It allows maintenance teams to move beyond purely reactive repairs. The consistent recording of gauge and meter readings, combined with work order history, reveals the subtle signs of impending intermittent failures. This historical and trending data empowers maintenance planners to make informed decisions about when to inspect, repair, or replace components. By understanding an asset's performance patterns through these collected readings, businesses can anticipate potential problems and schedule interventions before intermittent issues escalate into major operational disruptions. This shift toward proactive care significantly enhances asset reliability and operational stability.

A CMMS provides a centralized database where every work order, repair, and incident gets logged. When a technician responds to an intermittent failure, they create a detailed work order, noting the time, date, symptoms, and any observations. This system also allows for the manual input of equipment readings from sensors, meters, and gauges. Technicians regularly record values like temperature, vibration levels, pressure, or run-time hours directly into the CMMS. This collected data then forms a crucial historical record. Over time, this history builds a comprehensive picture of an asset's performance. The system can then show if similar issues have occurred before, even if individual events seemed unrelated. This historical data is crucial for identifying repeating patterns that a human might miss. For example, a series of brief shutdowns might consistently follow a period where a specific pressure gauge reading exceeded its normal range, indicating a subtle underlying issue. A CMMS's capacity to track manually entered equipment readings significantly contributes to proactive maintenance. It allows maintenance teams to move beyond purely reactive repairs. The consistent recording of gauge and meter readings, combined with work order history, reveals the subtle signs of impending intermittent failures. This historical and trending data empowers maintenance planners to make informed decisions about when to inspect, repair, or replace components. By understanding an asset's performance patterns through these collected readings, businesses can anticipate potential problems and schedule interventions before intermittent issues escalate into major operational disruptions. This shift toward proactive care significantly enhances asset reliability and operational stability.

Enhancing Technician Communication and Knowledge Sharing

A CMMS improves communication among maintenance teams. When a technician encounters an intermittent failure, they can add detailed notes and even attach images or videos to the work order. This information is instantly available to other team members. If another technician encounters a similar issue on a different shift, they can review the previous notes and potentially solve the problem much faster. This knowledge-sharing capability prevents the "reinventing the wheel" scenario where each technician starts from scratch. A CMMS also helps in assigning the right technician for the job. By tracking a technician's skills and certifications, the system can automatically assign the work order to the most qualified person, which increases the likelihood of a quick and accurate diagnosis.

Discover how streamlined maintenance processes can elevate production. Learn more.

Real-World Examples of Intermittent Failures and Asset Disruptions

Intermittent failures are not limited to one industry. They are a common headache across a range of business settings. Understanding specific examples helps illustrate the problem's scope.

Manufacturing

In a manufacturing plant, an intermittent failure could manifest as a brief stoppage on a conveyor belt. The belt stops for 30 seconds, then restarts on its own. The cause might be a faulty sensor that occasionally misfires, but because the issue is so short-lived, it's hard to trace. These brief stops create bottlenecks, reduce throughput, and frustrate line workers. A CMMS tracking these events by time and location can reveal a pattern: the shutdowns only happen when a specific machine on the line starts up, pointing to an electrical interference issue.

Transportation and Logistics

In the transportation sector, a delivery truck might experience a momentary loss of power while driving. The driver pulls over, restarts the vehicle, and it runs fine for the rest of the day. The issue might be a loose wire in the engine control unit. Without a diagnostic code, a mechanic would have a hard time finding the issue. A CMMS, with integrated vehicle telematics, could log the exact time and location of the power loss, providing a crucial clue for the mechanic.

Information Technology

Even in the world of IT, intermittent failures are common. A server might reboot itself randomly once a month. The system logs show no clear error code. The issue could be a microscopic crack on a circuit board that expands with heat. A CMMS, used to track server maintenance and incident history, can show that the reboots always happen after a period of heavy data processing, indicating a thermal issue.

Prevent Intermittent Failures Through Proactive Asset Management with CMMS

The fight against intermittent failures is an ongoing battle, but a Computerized Maintenance Management System, like the one developed by Mapcon Technologies, changes the terms of engagement. It turns a chaotic, unpredictable problem into a data-driven challenge. A CMMS gives teams the tools they need to track, analyze, and act on these subtle signs of asset distress. The data it provides doesn't just reveal a problem; it provides the insights necessary to predict and prevent future issues. The focus shifts from simply reacting to breakdowns to creating a culture of preventive care. This approach ensures greater asset longevity and a more stable, efficient operational environment, protecting businesses from the silent, costly threat of unpredictable breakdowns.

FAQs

What is an intermittent failure in maintenance?

An intermittent failure is a random, unpredictable malfunction that appears briefly and then disappears, making it difficult to diagnose and repair.

Why are intermittent failures costly for businesses?

They cause unplanned downtime, increase repair costs, and disrupt production schedules, often without a clear cause.

How can a CMMS help track intermittent failures?

A CMMS stores detailed work orders, equipment history, and sensor data to reveal patterns and help identify hidden issues.

What industries are most affected by intermittent failures?

Manufacturing, transportation, and IT commonly face intermittent failures that impact productivity and reliability.

Why should businesses choose MAPCON’s CMMS?

MAPCON’s CMMS offers powerful tracking tools, centralized data, and communication features that help maintenance teams manage unpredictable failures efficiently.

How does tracking equipment readings improve reliability?

Logging readings like temperature, vibration, and pressure into a CMMS highlights early warning signs and allows proactive maintenance.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!