Published: November 07, 2022 | Updated: January 14, 2026

Published: November 07, 2022 | Updated: January 14, 2026

Strategic Scheduling for Superior Maintenance Operations

Efficiently managing tasks requires a deliberate approach, particularly in complex operational environments. The idea that a plan defines "what" and a schedule dictates "when" underscores the necessity of both for successful execution. This principle holds immense relevance in the realm of maintenance, where effective scheduling directly impacts operational continuity and asset longevity. This discussion explores strategic scheduling for superior maintenance operations, focusing on its integration within a Computerized Maintenance Management System (CMMS).

The Advantages of Structured Scheduling

Implementing a structured scheduling approach provides several advantages that significantly influence productivity and organizational effectiveness.

Enhancing Organization and Direction

Schedules provide a framework for organizing activities, ensuring that tasks occur in a logical sequence and nothing falls through the cracks. This systematic arrangement prevents oversight and promotes a clear understanding of pending work. In maintenance, this organization manifests as a clear sequence of preventive maintenance tasks, inspections, and repair work. A well-organized schedule ensures that critical equipment receives attention at appropriate intervals, averting unexpected failures.

Fostering Professional Courtesy

Adherence to schedules demonstrates respect for the time of others and contributes to a professional work environment. When maintenance personnel follow a defined schedule, they arrive at job sites on time, prepared to execute tasks. This reliability builds trust with other departments and external vendors, facilitating smoother collaborations.

Driving Productivity and Focus

Structured scheduling directly contributes to increased productivity by providing clear direction and allowing for concentrated effort on assigned tasks. By allocating specific times for specific activities, maintenance teams avoid distractions and maintain focus. This targeted approach helps teams accomplish more within designated periods, leading to higher completion rates for work orders and improved overall maintenance performance.

Principles for Effective Scheduling

Achieving effective scheduling involves adopting several core principles that guide the creation and implementation of a practical timetable.

Selecting a Suitable System

The first step in effective scheduling involves identifying and adopting a system that aligns with operational needs. Options range from traditional wall calendars and simple alarm clocks to sophisticated scheduling software and integrated CMMS platforms. The most effective system is one that is readily accessible, intuitive to use, and capable of handling the complexity of maintenance tasks.

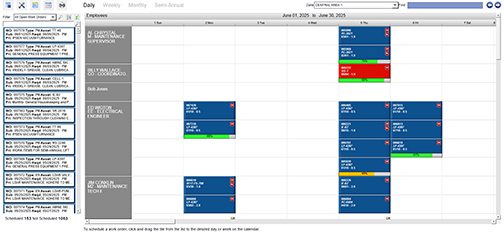

For example, a CMMS offers a centralized platform for managing all maintenance-related schedules, providing a comprehensive overview that manual methods simply cannot match. This includes setting up recurring preventive maintenance (PM) schedules, managing ad-hoc corrective work orders, and tracking the progress of each task. The system should facilitate easy entry, modification, and retrieval of schedule information, making it a functional tool for daily operations.

Developing Comprehensive Task Lists

Before any scheduling occurs, creating an exhaustive list of all upcoming activities is essential. This includes routine preventive maintenance tasks, planned inspections, and upcoming work projects. This list might encompass quarterly HVAC inspections, annual calibration of critical machinery, or unexpected repairs. A CMMS proves invaluable here, as it can store and manage an extensive database of assets, their associated maintenance requirements, and historical work orders. This enables maintenance managers to generate accurate and complete task lists, ensuring that no vital activity is overlooked. The system can even flag upcoming tasks based on predefined intervals or meter readings, automating the list generation process.

Prioritizing Activities

Not all tasks possess equal urgency or importance. Prioritizing activities ensures that critical work receives immediate attention. This involves categorizing tasks based on their impact on operations, safety, and regulatory compliance. A CMMS greatly assists in this process by allowing users to assign priority levels to work orders.

For instance, a CMMS can flag a critical equipment breakdown as "urgent" while a routine inspection might be labeled "important but not urgent." This prioritization helps maintenance teams allocate resources effectively, addressing high-priority issues first to minimize downtime and prevent costly failures. The system can also be configured to generate alerts for overdue high-priority tasks, ensuring accountability.

Avoiding Overscheduling

While a structured schedule promotes productivity, cramming too many activities into a single day can lead to burnout and inefficiency. Effective scheduling accounts for realistic timeframes, including buffers for unexpected delays or unforeseen complications. For maintenance, this means allocating sufficient time for travel between job sites, acquiring necessary parts, and handling unexpected minor issues that arise during a task.

A CMMS can help prevent over-scheduling by providing visual representations of resource availability and workload. It can highlight potential conflicts when attempting to assign too many tasks to a single technician or piece of equipment, allowing managers to adjust schedules accordingly. This ensures that maintenance personnel have adequate time to complete tasks thoroughly and safely.

Practicing Diligence and Follow-Through

The effectiveness of any schedule relies heavily on diligent adherence and consistent follow-through. Creating a schedule is only the first step; commitment to executing the planned activities brings positive results. In maintenance, this translates to technicians consistently performing scheduled PMs, completing assigned work orders, and accurately documenting their efforts within the CMMS. The CMMS acts as a central repository for this diligence, recording completion times, technician notes, and any parts used. This data provides valuable insights for future scheduling and performance analysis, demonstrating the tangible benefits of consistent application.

Leveraging Delegation

Delegation is a powerful tool for distributing workload and achieving more comprehensive task completion. Assigning tasks to appropriate team members ensures that deadlines are met without overstretching individual capacities. A CMMS facilitates delegation by allowing managers to assign work orders to specific technicians or teams, track their progress, and monitor their workload. This capability ensures that tasks are distributed equitably and that the right person with the right skills handles each job. Furthermore, the CMMS can provide visibility into technician availability and certifications, assisting in intelligent delegation decisions.

Setting Boundaries with "No"

Understanding when to decline additional commitments is crucial for maintaining a realistic and manageable schedule. Taking on too many responsibilities can lead to missed deadlines and compromised quality of work. For maintenance, this might involve politely declining requests for non-critical, ad-hoc tasks that would disrupt a meticulously planned PM schedule. A CMMS helps reinforce these boundaries by providing clear visibility into existing commitments and workloads, supporting decisions to defer or decline new, unscheduled work that would negatively impact higher-priority tasks. It offers objective data to explain why certain requests cannot be immediately accommodated.

Incorporating Breaks and Leisure Time

Regular breaks and dedicated leisure time are not luxuries but necessities for sustaining productivity and preventing burnout. Scheduling short breaks throughout the workday allows for mental refreshment and renewed focus. Similarly, carving out time for personal enjoyment and relaxation outside of work promotes a healthy work-life balance, which in turn enhances overall well-being and job performance.

While a CMMS primarily focuses on work-related scheduling, its ability to help manage and complete work efficiently can indirectly contribute to a better work-life balance by freeing up time. Efficient work management allows individuals to complete their tasks within working hours, reducing the need for overtime and providing more opportunities for personal time.

Discover how streamlined maintenance processes can elevate production. Learn more.

Conducting Regular Reviews

After completing a segment of the schedule, a review process helps assess effectiveness and identify areas for improvement. This involves evaluating whether daily or weekly goals were met and understanding the reasons for any discrepancies. For maintenance operations, this means reviewing completed work orders within the CMMS to assess task completion rates, actual versus estimated time, and any reported issues. The CMMS generates reports and analytics that offer insights into scheduling accuracy, resource utilization, and equipment performance. This review process helps refine future scheduling strategies, making them more precise and responsive to actual operational demands.

Unified Work Order Management

The CMMS acts as a central repository for all work orders, whether they are preventive or corrective. This unified system allows maintenance managers to create, assign, track, and close work orders efficiently. For example, a CMMS can automatically generate preventive maintenance work orders based on predefined schedules (time-based, meter-based, or event-based), ensuring that equipment receives attention at the right intervals. When an unforeseen breakdown occurs, a new corrective work order can be immediately entered into the system, prioritized, and assigned to available technicians. This centralized management provides a clear, real-time overview of all maintenance activities, preventing delays and ensuring accountability.

Enhanced Resource Allocation

A CMMS significantly improves resource allocation by providing detailed insights into technician availability, skill sets, and current workloads. When scheduling a task, the system can show the availability of each technician. This help to prevent over-allocation or under-utilization of personnel. It also manages inventory, indicating the availability of necessary parts and materials before a job begins. This capability ensures that technicians have the right tools and components at their disposal, minimizing delays caused by missing items or unassigned personnel.

Data-Driven Decision Making

Beyond scheduling, a CMMS collects vast amounts of data on maintenance activities, equipment performance, and costs. This data is invaluable for informed decision-making. Managers can generate reports on key performance indicators (KPIs) such as mean time to repair (MTTR), mean time between failures (MTBF), and adherence to PM schedules. Analyzing this data helps identify recurring problems, pinpoint inefficient processes, and justify investments in new equipment or training. The ability to measure productivity and review results with objective data allows for continuous improvement in maintenance strategies and overall operational effectiveness.

Effective scheduling, particularly when supported by a comprehensive CMMS, significantly elevates maintenance operations. It moves maintenance from a reactive to a proactive discipline, ensuring that assets perform reliably and efficiently. By embracing structured scheduling and leveraging the capabilities of a CMMS, organizations establish a foundation for sustained operational excellence and enhanced asset longevity.

FAQs

Why is strategic scheduling important for maintenance operations?

Strategic scheduling ensures tasks are completed in a logical order, prevents missed work, and supports operational continuity.

How does a CMMS improve maintenance scheduling?

A CMMS centralizes schedules, automates recurring work orders, tracks progress, and provides visibility into workloads and resources.

What are the benefits of prioritizing maintenance tasks?

Prioritization ensures critical equipment receives timely attention, reduces downtime, and optimizes resource allocation.

How can over-scheduling affect maintenance teams?

Too many tasks in a short timeframe can lead to burnout, inefficiency, and compromised work quality.

How does unified work order management enhance maintenance efficiency?

A CMMS consolidates preventive and corrective work orders, streamlines assignment, and enables real-time tracking and accountability.

Why is reviewing schedules and performance critical?

Regular reviews help identify gaps, improve resource allocation, refine future planning, and drive continuous operational improvement.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!