Published: September 30, 2024 | Updated: October 09, 2025

Published: September 30, 2024 | Updated: October 09, 2025

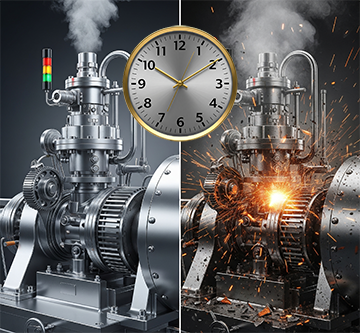

Mastering Asset Reliability: Decoding Mean Time Between Failures

Being able to decode Mean Time Between Failures (MTBF) forms a crucial part of effective asset management. This essential calculation provides insights into equipment performance, safety protocols, design effectiveness, and overall operational reliability. This discussion explores the core meaning of mean time between failures, its calculation, the significance of its results, its advantages and disadvantages, and how a computerized maintenance management system greatly aids its application.

Being able to decode Mean Time Between Failures (MTBF) forms a crucial part of effective asset management. This essential calculation provides insights into equipment performance, safety protocols, design effectiveness, and overall operational reliability. This discussion explores the core meaning of mean time between failures, its calculation, the significance of its results, its advantages and disadvantages, and how a computerized maintenance management system greatly aids its application.

Defining Mean Time Between Failures

MTBF quantifies a system's reliability, representing the average operational duration of a system or component before an unplanned cessation of function. Industries such as manufacturing, technology, and aerospace frequently employ this metric. It offers a powerful tool for forecasting equipment lifespan and establishing effective maintenance schedules. This measurement specifically addresses the time an asset remains operational and available for its intended function, providing a key indicator of its inherent dependability.

Calculating Mean Time Between Failures

The MTBF calculation exclusively accounts for unexpected maintenance events. It disregards planned maintenance activities, including routine inspections, system recalibrations, or scheduled component replacements. The formula for determining MTBF involves a straightforward division: total operational hours by the number of failures occurring within a defined period.

Consider a practical scenario: a critical conveyor system in an automotive assembly plant operates for 6,000 hours over a six-month span, experiencing three unforeseen breakdowns. To determine its MTBF, divide 6,000 hours by 3 failures, yielding an MTBF of 2,000 hours.

This signifies that, on average, this conveyor system operates for 2,000 hours between failures. Such an immediate result, however, needs deeper analysis. This initial calculation presents a general average and doesn't fully capture the nuances of individual asset performance. A complete assessment necessitates factoring in design considerations, assembly quality, the efficacy of preventive maintenance routines, and actual operational practices. For instance, a complex robotic arm in a precision manufacturing facility, despite a high MTBF, might still experience critical failures due to overlooked design flaws in a specific joint, or a lack of precise lubrication schedules.

The Importance of MTBF Results

Leveraging MTBF data, alongside failure codes, insights from root cause analysis, and another critical metric, Mean Time To Repair (MTTR), allows for significant adjustments to preventive maintenance approaches. This comprehensive information enables organizations to:

- Reduce instances of unscheduled operational interruptions.

- Lower overall operational expenditures.

- Elevate production output and operational effectiveness.

Effective utilization of MTBF data extends its influence beyond immediate maintenance strategies. It provides valuable insights for managing asset life cycles. For example, the depreciation value of a piece of heavy machinery in a construction company versus the cost of replacing it or acquiring a new model becomes clearer with accurate MTBF data. A higher MTBF suggests a longer useful life, potentially delaying replacement costs and improving return on investment.

In contrast, a consistently low MTBF might signal an aging or problematic asset nearing the end of its economic life, prompting earlier replacement considerations. This analytical approach also greatly enhances inventory management. Maintenance, Repair, and Operations (MRO) inventory purchasing becomes more precise and responsive. Knowing the expected operational intervals between failures for specific components allows purchasing departments to anticipate demand for spare parts, avoiding both overstocking and critical shortages. A good example is a fleet of delivery vehicles; knowing the MTBF for specific components like brake systems or transmissions allows the logistics company to stock parts more efficiently, reducing vehicle downtime and ensuring timely deliveries.

Discover how streamlined maintenance processes can elevate production. Learn more.

Advantages of Calculating MTBF

Calculating MTBF offers several compelling benefits across various operational facets:

- Manufacturers’ Perspective: MTBF assists manufacturers in evaluating anticipated product lifespans and validating product reliability. A manufacturer of industrial pumps, for instance, cites a high MTBF as a selling point, assuring customers of extended, trouble-free operation.

- Risk Identification: The calculation aids in identifying potential operational risks. This understanding holds significant value for maintenance personnel, production line teams, and the manufacturer. Identifying assets with historically lower MTBF values allows for proactive risk mitigation strategies, such as increased monitoring or pre-emptive component replacement.

- Quality Assessment: MTBF serves as an indicator of the quality of materials and components employed in the production process. A decline in MTBF for a particular asset type might point to issues with a batch of raw materials or a newly introduced supplier.

- Effectiveness of Maintenance: Use MTBF to gauge the efficacy of preventive maintenance and repair procedures. Do current maintenance activities occur at the right intervals and comprise the appropriate tasks to ensure maximum operational uptime? For example, if a series of industrial ovens consistently experience failures just before their scheduled preventive maintenance, it might indicate that the maintenance interval is too long or the scope of work needs adjustment.

- Performance Comparison: MTBF facilitates performance comparisons among different models and brands of similar products. An agricultural business considering new tractors might compare the MTBF ratings of various manufacturers to make an informed purchasing decision, favoring models with a demonstrated history of longer operational periods between breakdowns.

Disadvantages of MTBF

While offering numerous advantages, MTBF also presents a few limitations to acknowledge:

- Incomplete Insight: MTBF alone offers no information regarding the specific causes or severity of failures. It provides only a restricted view of asset dependability. To gain a comprehensive understanding, organizations need to incorporate other factors and utilize additional metrics. For example, a low MTBF for a packaging machine might indicate frequent breakdowns, but without root cause analysis, you won't know if the issue stems from operator error, component wear, or a design flaw.

- Susceptibility to Outliers: External factors can distort the MTBF calculation. Consider a scenario in a food processing plant where a sudden power surge, triggered by a lightning strike, damages a critical processing unit. This constitutes an unplanned breakdown. However, including this event in the MTBF calculation when assessing the effectiveness of routine maintenance or the intrinsic design of the machine would present a skewed picture. The failure was not a result of normal operational wear or maintenance oversight, but an extraordinary external force. Similarly, if a forklift experiences damage from a collision with another vehicle, that incident, while causing downtime, does not reflect the inherent reliability of the forklift's mechanical systems under normal operating conditions. These exceptional events must undergo separate analysis to avoid misrepresenting the true operational reliability derived from routine failures.

The Role of Computerized Maintenance Management Systems (CMMS)

Many industries deploy CMMS software to maintain organized maintenance departments. This software significantly enhances the application and benefits derived from MTBF. A CMMS acts as a central repository for vast amounts of crucial operational data:

Many industries deploy CMMS software to maintain organized maintenance departments. This software significantly enhances the application and benefits derived from MTBF. A CMMS acts as a central repository for vast amounts of crucial operational data:

- Central Database: A CMMS stores comprehensive information on assets, inventory, preventive maintenance (PM) schedules, and work orders. Users gain ready access to all asset details, maintenance histories, and equipment readings. This centralized data collection is vital for accurate MTBF calculations and trend analysis.

- Equipment Readings: The system allows for setting up regular cycles of recording various equipment readings, such as PSI, temperature, lubrication levels, running speed, and vibration levels. With these readings readily available, users can chart the operational progress of assets. This detailed monitoring enables organizations to refine their PM schedules dynamically. For instance, rising vibration levels on a motor, tracked by the CMMS, might trigger a PM work order before an actual failure occurs, potentially increasing the MTBF.

- Inventory Management: A CMMS improves efficiency and MTBF through automated, accurate stock information. It tracks quantities of spare parts and helps organize the stockroom, ensuring critical components are available when needed. This reduces downtime related to parts shortages, which indirectly contributes to a higher MTBF by reducing the duration of unplanned outages.

- Reports: The system generates key performance indicator (KPI) reports and other analyses that provide improved maintenance management oversight. These reports can specifically highlight MTBF trends, identify problematic assets, and assess the impact of maintenance strategies on reliability. This data-driven approach supports informed decision-making for proactive maintenance and asset lifecycle planning.

For example, a chemical processing plant utilizes a CMMS to track a fleet of pumps. The system logs every operational hour, every unscheduled shutdown, and the precise time of each failure. The CMMS then automatically calculates the MTBF for each pump model. This allows the maintenance team to identify models with lower MTBFs, investigate the common failure modes for those models using historical work order data also stored in the CMMS, and then adjust their preventive maintenance plans specifically for those problematic pumps.

They might increase the frequency of lubrication checks, replace wear components earlier, or even consider replacing a particular pump model if its MTBF consistently falls below acceptable levels. The CMMS also tracks spare parts inventory for these pumps, ensuring that when a part is needed for a repair, it is readily available, thus minimizing the Mean Time To Repair (MTTR) and indirectly supporting overall operational uptime, contributing to higher effective MTBF values.

Driving Continuous Improvement Through Reliability Metrics

Mastering the intricacies of mean time between failures equips organizations to proactively address and mitigate unscheduled interruptions within their facilities. Asset failures stem from various reasons, each necessitating thorough analysis and resolution of underlying causes. Consistent tracking and detailed analysis of MTBF furnish critical data essential for elevating asset dependability. Focusing on improving MTBF and overall asset reliability unlocks considerable advantages across an organization, impacting everything from the day-to-day operations on the factory floor to high-level strategic decisions made in executive boardrooms. The pursuit of enhanced reliability is a continuous journey that yields enduring dividends.

FAQs

What does Mean Time Between Failures (MTBF) quantify in asset management?

MTBF quantifies a system's reliability by representing the average operational duration of a component or system before an unexpected, unplanned cessation of function.

How is the MTBF calculation performed for industrial equipment?

MTBF is calculated by dividing the total operational hours of an asset by the number of unplanned failures that occurred within a defined period.

How does MTBF data improve spare parts and inventory management?

Knowing the expected MTBF for specific components allows purchasing to anticipate demand for spare parts more precisely, avoiding both overstocking and critical shortages.

What is a key advantage of calculating MTBF from a manufacturer's perspective?

MTBF assists manufacturers in evaluating anticipated product lifespans and validating product reliability, often citing a high MTBF as a selling point.

How does a CMMS aid in accurately applying and analyzing MTBF?

A CMMS acts as a central repository, automatically tracking operational hours, logging all unscheduled shutdowns, and generating reports that highlight MTBF trends for analysis.

How does the CMMS from MAPCON help a plant proactively increase its MTBF?

MAPCON's CMMS can track equipment readings like vibration levels, which can trigger a preventive maintenance work order before an actual failure occurs, thus extending the MTBF.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!