Published: October 22, 2025 | Updated: October 23, 2025

Published: October 22, 2025 | Updated: October 23, 2025

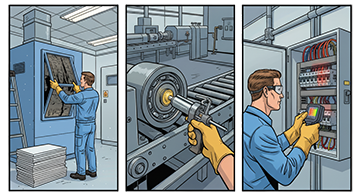

How to Create a Preventive Maintenance Program That Works

Preventive maintenance matters for any organization that relies on equipment or facilities. Instead of waiting for breakdowns, managers plan inspections, replacements, and adjustments ahead of time. A CMMS (Computerized Maintenance Management System) makes this approach easier to organize and track. This article explains how preventive maintenance works, its benefits, and how a CMMS strengthens the process.

Preventive maintenance matters for any organization that relies on equipment or facilities. Instead of waiting for breakdowns, managers plan inspections, replacements, and adjustments ahead of time. A CMMS (Computerized Maintenance Management System) makes this approach easier to organize and track. This article explains how preventive maintenance works, its benefits, and how a CMMS strengthens the process.

What Is Preventive Maintenance and Why Does It Matter?

Preventive maintenance means scheduling inspections, servicing, and minor repairs before assets fail. Unlike reactive maintenance—where teams scramble after something breaks—preventive maintenance protects safety, cuts downtime, and stretches asset life.

For example, a hospital checks generators monthly and replaces belts every six months. A food plant lubricates conveyor systems based on usage hours rather than waiting for failure.

A CMMS supports these efforts by storing asset histories, automating reminders, and issuing work orders. Instead of guessing when a repair is due, the system provides accurate, timely instructions.

The Four Pillars of a Strong Preventive Maintenance Program

1. Inspection

Inspections keep teams alert to wear, leaks, and safety risks. In manufacturing, vibration sensors on motors need weekly review; in property management, fire alarms demand routine checks.

A CMMS organizes inspection routes, logs results on mobile devices, and creates corrective tasks when issues appear.

2. Detection

Detection identifies early warning signs like noise, leaks, or temperature fluctuations. University maintenance staff, for instance, monitor pumps and HVAC systems for small anomalies.

A CMMS can integrate with sensors to capture data and issue alerts when readings exceed safe ranges, reducing human error and catching failures earlier.

3. Correction

Correction addresses problems found during inspections. Tasks may include tightening bolts, replacing belts, or cleaning vents.

CMMS software makes this step efficient by generating work orders, assigning tasks, and tracking completion. A school district, for instance, uses a CMMS to schedule quarterly filter changes across multiple buildings.

4. Prevention

Prevention means learning from failures and adjusting schedules. If pumps fail too often, managers review usage, installation, and maintenance history.

A CMMS provides these analytics, helping managers fine-tune schedules and prevent repeat problems.

Discover how streamlined maintenance processes can elevate production. Learn more.

Types of Preventive Maintenance: Time-Based Vs Usage-Based

- Time-based maintenance follows the calendar: monthly inspections, quarterly filter changes, annual safety checks.

- Usage-based maintenance depends on runtime or cycles: oil changes every 5,000 miles, motor servicing after 2,000 operating hours.

Most industries adopt a hybrid. For instance, factories perform monthly inspections but schedule major overhauls after specific usage hours.

A CMMS handles both, ensuring calendar events and runtime triggers generate timely work orders.

Benefits of Preventive Maintenance

Preventive maintenance offers several advantages:

- Reduced downtime: Failures happen less often, keeping production lines, classrooms, and offices running.

- Improved safety: Reliable equipment prevents accidents.

- Lower long-term costs: Emergency repairs and overtime charges shrink.

- Extended asset life: Systems last longer, easing capital planning.

For example, a food processing facility switched to preventive maintenance and saw 20% more uptime, 30% lower repair costs, and fewer customer complaints.

Reactive vs Preventive Maintenance: Why the Shift Matters

Reactive maintenance drains budgets through emergency labor, replacement costs, and production losses. When HVAC fails on a summer day or a pipe bursts in a school, repairs cost far more than scheduled upkeep.

Preventive maintenance avoids these scenarios. In energy production, a single unplanned shutdown may exceed an annual maintenance budget. Hospitals that skip inspections risk patient safety if systems fail.

A CMMS shows the financial contrast by tracking downtime, unplanned work, and total costs. Data makes the case for shifting from reactive to preventive strategies.

How to Build a Preventive Maintenance Program with CMMS

Step 1: Inventory Assets

List all assets with details like model, age, and service history. Without inventory, scheduling collapses.

A CMMS acts as a central repository. Many organizations use QR codes to pull up maintenance records instantly.

Step 2: Prioritize Assets

Not all equipment carries the same risk. Critical systems—boilers, safety alarms, clinical devices—need higher priority.

CMMS dashboards reveal which assets generate most work orders or costs, guiding resource allocation.

Step 3: Schedule Tasks

Set time-based and usage-based tasks. For example, bearings get lubricated every 200 hours, filters changed monthly, safety inspections done quarterly.

CMMS platforms manage schedules, send alerts, and track overdue tasks.

Step 4: Assign and Train

Define roles clearly and train staff on CMMS use. Hospitals train staff to log anomalies and ensure maintenance crews act fast.

Step 5: Monitor and Improve

Track metrics like downtime, reactive vs preventive work, and repair costs. Adjust schedules accordingly.

A CMMS supplies dashboards and reports, helping teams refine practices and retire inefficient assets.

Risk Reduction Through Preventive Maintenance

Preventive programs reduce risks to both people and property.

- People: Maintained safety systems, clean air, and safe machinery protect workers and occupants.

- Property: Inspections prevent water damage, fires, and equipment destruction.

A CMMS reduces risk by storing compliance records, reminding teams of regulatory deadlines, and ensuring safety-critical tasks stay visible.

Industry Examples

- Healthcare: Hospitals use CMMS tools to manage sterilizers, HVAC, and backup generators, ensuring compliance and patient safety.

- Manufacturing: Food plants schedule lubrication and washing tasks by runtime, cutting breakdowns and maintaining product quality.

- Education: Schools use preventive schedules for fire extinguishers, HVAC, and roofs, preventing emergencies during the school year.

- Real Estate: Property managers rely on CMMS to oversee elevators, HVAC, and plumbing, keeping tenants satisfied and costs stable.

How a CMMS Strengthens Preventive Maintenance

| Area |

Role of CMMS |

| Asset Inventory |

Stores data, photos, and manuals; supports QR/barcode scanning. |

| Scheduling |

Sets recurring tasks and usage triggers; issues reminders. |

| Work Orders |

Assigns, tracks, and closes tasks with labor and parts logged. |

| Reporting |

Provides dashboards and cost breakdowns; compares reactive vs preventive work. |

| Safety |

Manages compliance records and inspection reminders. |

| Improvement |

Identifies recurring failures, enabling schedule adjustments. |

Solving Common Preventive Maintenance Challenges

- Overlooking minor assets: Solve by performing complete walk-throughs and tagging items in the CMMS.

- Missing documentation: Upload manuals and specs into the CMMS for quick reference.

- Staff overload: Schedule preventive tasks during slower periods and use CMMS to balance workload.

- Cultural resistance: Share CMMS data showing fewer emergencies and lower costs after adopting preventive routines.

Why Preventive Maintenance Plus CMMS Delivers Strong Results

Preventive maintenance reduces downtime, enhances safety, and cuts long-term repair costs. When combined with a capable CMMS, organizations gain structure, accountability, and actionable data. Across industries—from healthcare to real estate—teams that adopt preventive programs supported by CMMS technology achieve measurable improvements that reactive strategies cannot match.

FAQs

What is preventive maintenance?

Preventive maintenance involves scheduled inspections, servicing, and repairs to prevent equipment failures before they happen.

How does a CMMS help with preventive maintenance?

A CMMS schedules tasks, tracks work orders, and keeps records so teams can reduce downtime and extend asset life.

What are examples of preventive maintenance tasks?

Examples include lubrication, filter replacement, safety inspections, and calibration of equipment.

Can MAPCON CMMS handle usage-based maintenance?

Yes, MAPCON CMMS tracks runtime hours or cycles and automatically triggers maintenance tasks when thresholds are met.

Why should businesses shift from reactive to preventive maintenance?

Preventive maintenance reduces emergency repair costs, improves safety, and extends the lifespan of assets.

Is preventive maintenance cost-effective for small organizations?

Yes, even small organizations benefit by lowering repair expenses and avoiding major disruptions.

MAPCON | 800-922-4336

MAPCON CMMS software empowers you to plan and execute PM tasks flawlessly, thanks to its wealth of features and customizable options. Want to see it for yourself? Click the button below to get your FREE 30-day trial of MAPCON!

Try It FREE!